Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

AR direct roving finds applications in various composite manufacturing processes including pultrusion, filament winding, and resin transfer molding (RTM), among others. Its properties make it particularly suitable for applications where the composite material will be exposed to harsh environments or where high strength and durability are required.

while both AR roving and C-glass roving are used as reinforcement materials in composite manufacturing, AR roving offers superior resistance to alkaline environments, making it suitable for specific applications where this property is critical. C-glass roving, on the other hand, is more versatile and widely used across various industries and applications.

|

Model |

Ingredient |

Alkali content |

Single fiber diameter |

Number |

Strength |

|

CC11-67 |

C |

6-12.4 |

11 |

67 |

>=0.4 |

|

CC13-100 |

13 |

100 |

>=0.4 |

||

|

CC13-134 |

13 |

134 |

>=0.4 |

||

|

CC11-72*1*3 |

11 |

216 |

>=0.5 |

||

|

CC13-128*1*3 |

13 |

384 |

>=0.5 |

||

|

CC13-132*1*4 |

13 |

396 |

>=0.5 |

||

|

CC11-134*1*4 |

11 |

536 |

>=0.55 |

||

|

CC12-175*1*3 |

12 |

525 |

>=0.55 |

||

|

CC12-165*1*2 |

12 |

330 |

>=0.55 |

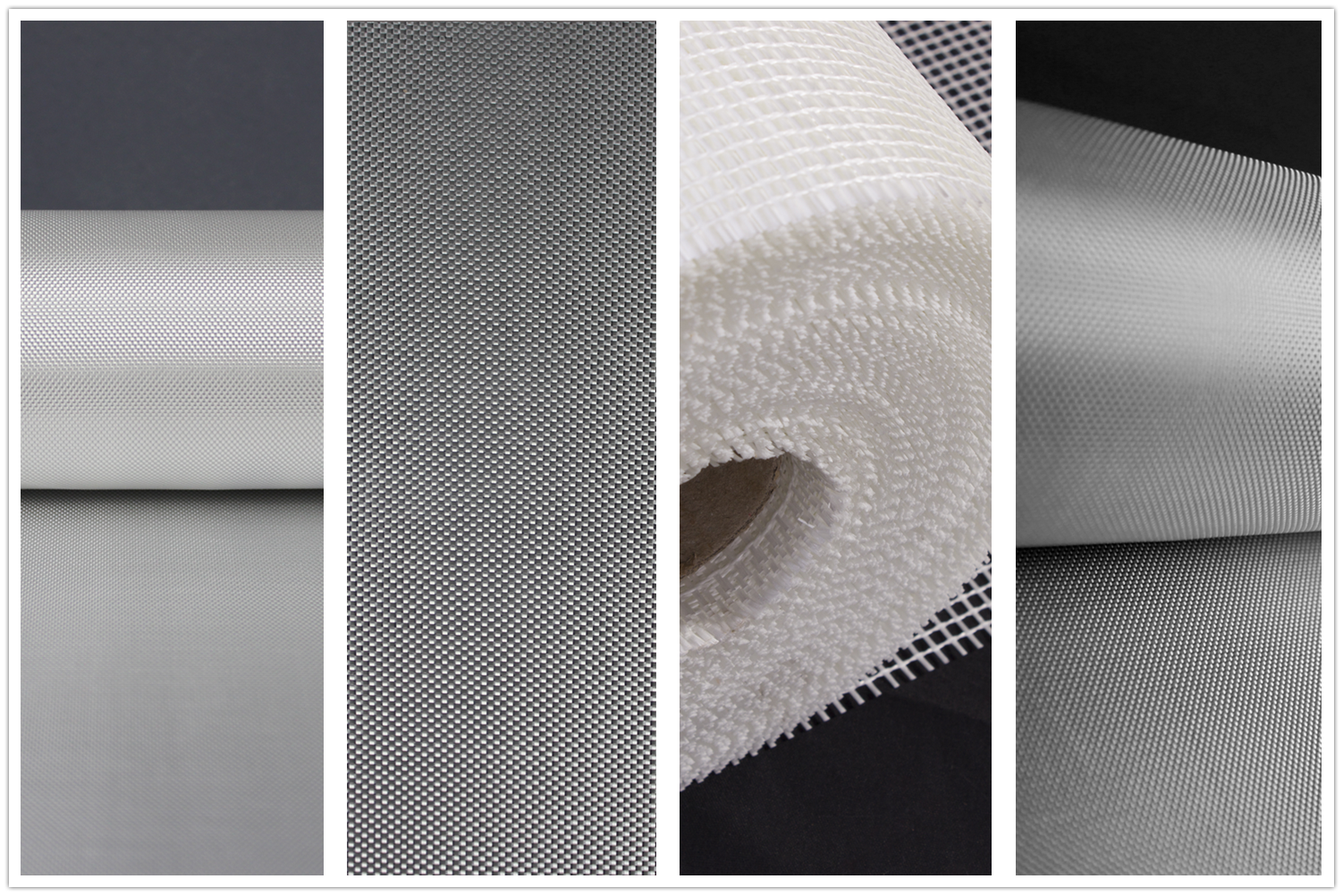

C-glass fiberglass roving, also known as conventional or chemical-resistant glass roving:

| Package height mm (in) |

260(10) |

| Package inside diameter mm(in) |

100(3.9) |

| Package outside diameter mm(in) |

270(10.6) |

| Package Weight kg(lb) |

17(37.5) |

| Number of layers |

3 |

4 |

| Number of doffs per layer |

16 |

|

| Number of doffs per pallet |

48 |

64 |

| Net Weight per pallet kg(lb) |

816(1799) |

1088(2398.6) |

| Pallet Length mm(in) |

1120(44) |

|

| Pallet Width mm(in) |

1120(44) |

|

| Pallet height mm(in) |

940(37) |

1200(47) |

Package of Roving:

With pallet.

Store Of AR Roving:

In its original packaging or on racks designed for fiberglass roving storage. Keep the roving rolls or spools upright to prevent deformation and maintain their shape.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.