Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

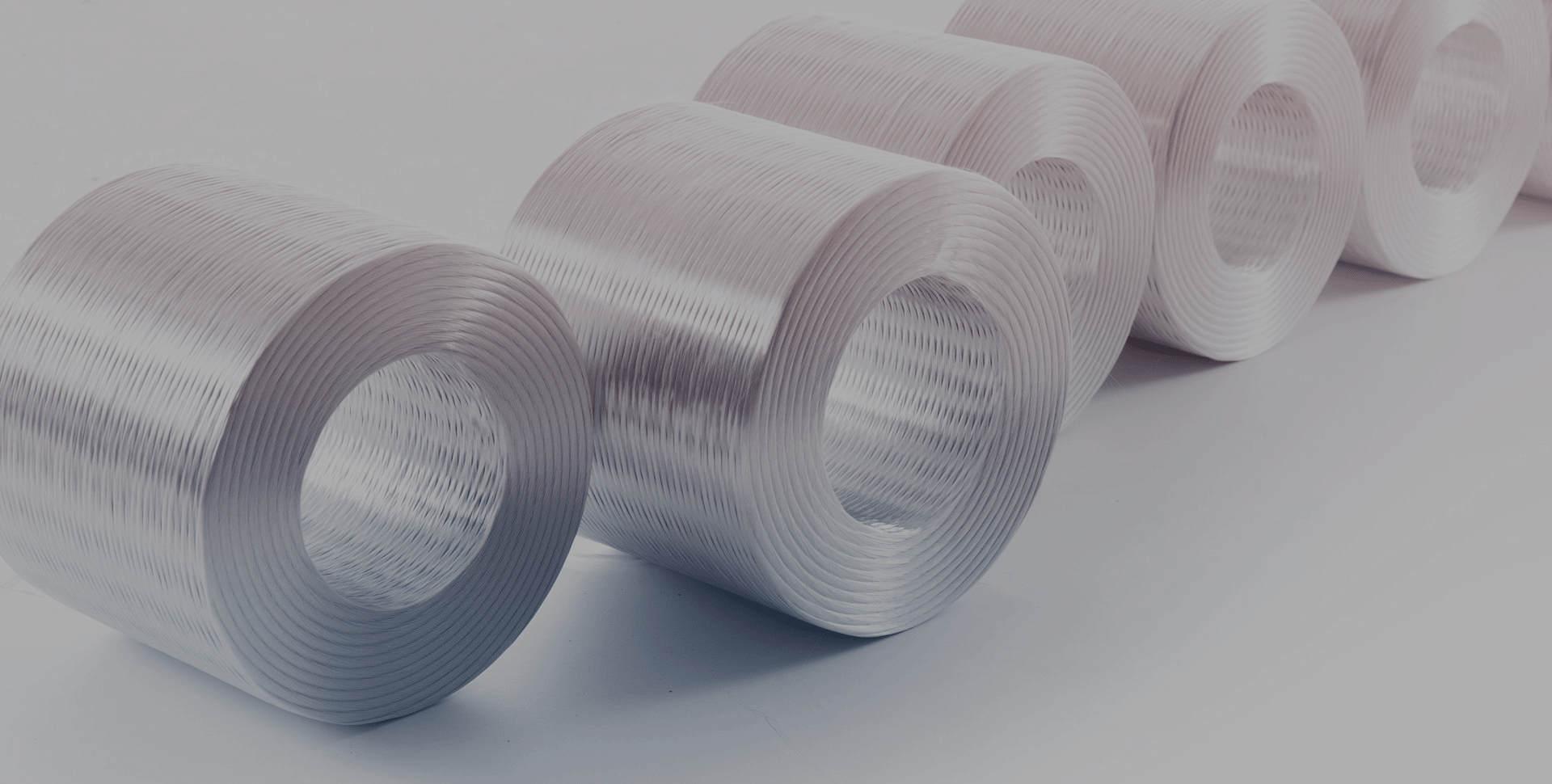

Fiberglass assembled roving features:

• Good wet-out in resins

• Good dispersion

• Good static control

• Suitable for soft mats

Looking to enhance the strength and durability of your composite materials? Fiberglass assembled roving is the solution you need. This high-performance reinforcement material is made by aligning continuous glass fiber strands into a single roving package. With its exceptional mechanical properties and excellent wet-out capability, fiberglass assembled roving provides superior strength and stiffness to composite products. It is commonly used in various industries, including automotive, aerospace, and wind energy, for applications such as pultrusion, filament winding, and sheet molding compounds. Choose fiberglass assembled roving to optimize the performance and reliability of your composite materials. Contact us today to learn more about our fiberglass assembled roving options and find the perfect solution for your specific requirements.

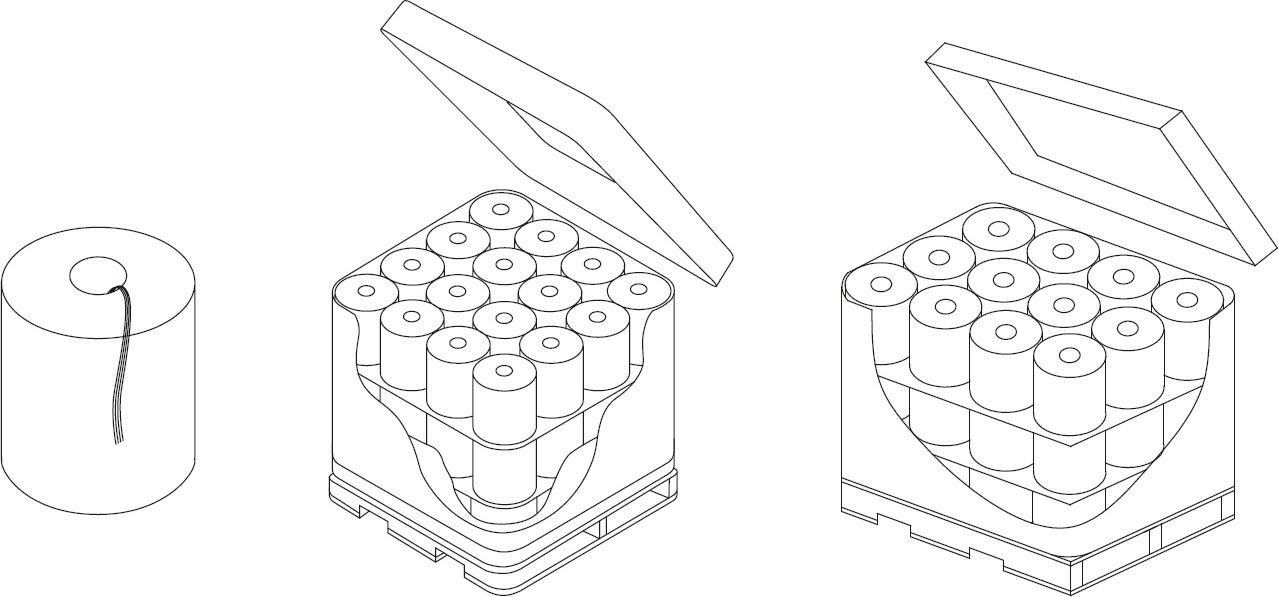

Unless otherwise specified, glass fiber products should be stored in a dry, cool, and moisture-proof place.

Glass fiber products should be kept in their original packaging before use. Room temperature and humidity should be kept at -10℃~35℃ and ≤80% respectively.

To ensure safety and avoid damaging products, the stacking height of trays should not exceed three layers.

When the trays are stacked in 2 or 3 layers, special attention should be paid to correctly and smoothly moving the top tray.

We have many types of fiberglass roving: panel roving, spray up roving, SMC roving, direct roving,c glass roving, and fiberglass roving for chopping.

| Example | E6R12-2400-512 |

| Glass Type | E6-Fiberglass assembled roving |

| Assembled Roving | R |

| Filament Diameter μm | 12 |

| Linear Density, tex | 2400, 4800 |

| Size Code | 512 |

Unless otherwise specified, the fiberglass products should be stored in a dry, cool, and moisture-proof area.

The fiberglass products should remain in their original package prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively.

To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high.

When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.

Our fiberglass mats are of several types: fiberglass surface mats, fiberglass chopped strand mats, and continuous fiberglass mats. The chopped strand mat is divided into emulsion and powder glass fiber mats.

| Linear Density (%) | Moisture Content (%) | Size Content (%) | Stiffness (mm) |

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ± 4 | ≤ 0.10 | 0.50 ± 0.15 | 110 ± 20 |

The product can be packed on pallets or in small cardboard boxes.

| Package height mm (in) |

260 (10.2) |

260 (10.2) |

| Package inside diameter mm (in) |

100 (3.9) |

100 (3.9) |

| Package outside diameter mm (in) |

270 (10.6) |

310 (12.2) |

| Package weight kg (lb) |

17 (37.5) |

23 (50.7) |

| Number of layers |

3 |

4 |

3 |

4 |

| Number of doffs per layer |

16 |

12 |

||

| Number of doffs per pallet |

48 |

64 |

36 |

48 |

| Net weight per pallet kg (lb) |

816 (1799) |

1088 (2399) |

828 (1826) |

1104 (2434) |

| Pallet length mm (in) | 1120 (44.1) | 1270 (50) | ||

| Pallet width mm (in) | 1120 (44.1) | 960 (37.8) | ||

| Pallet height mm (in) | 940 (37) | 1200 (47.2) | 940 (37) | 1200 (47.2) |

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.