Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Fiberglass LFT (Long Fiber Thermoplastic) roving is a continuous bundle of E-glass or other glass fibers designed for reinforcing thermoplastic materials in composite production. It is typically used in the automotive, aerospace, and construction industries to add strength and stiffness to plastic components. The long fibers in LFT roving result in superior mechanical properties compared to traditional short-fiber composites. Fiberglass LFT roving also is fiberglass direct roving.

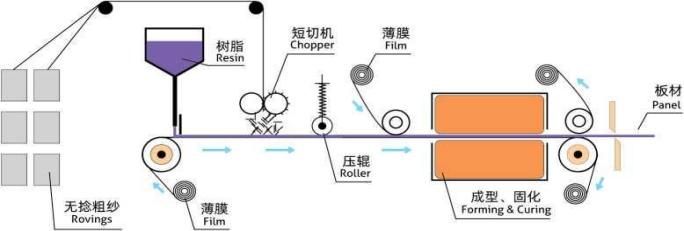

Continuous Panel Molding Process

The continuous panel molding process typically involves the following steps:

1. Raw Material Preparation: Raw materials such as fiberglass, resin, and additives are prepared in the correct proportions according to the panel specifications.

2. Mixing: The raw materials are fed into a mixing machine to ensure thorough blending and homogeneity of the mixture.

3. Molding: The mixed materials are then fed into a continuous molding machine, which forms them into the desired panel shape. This may involve using molds, compression, and other shaping techniques.

4. Curing: The formed panels are then moved through a curing process, where they are subjected to heat, pressure, or chemical reactions to set and harden the materials.

5. Trimming and Finishing: After the panels have cured, any excess material or flash is trimmed off, and the panels may undergo additional finishing processes such as sanding, painting, or coating.

6. Quality Control: Throughout the process, quality control checks are performed to ensure the panels meet the specified standards for thickness, surface finish, and structural integrity.

7. Cutting and Packaging: Once the panels are complete and inspected, they are cut to the desired lengths and packaged for shipping and distribution.

These steps may vary depending on the specific materials and the design requirements of the panels, but they provide a general overview of the continuous panel molding process.

We have many types of fiberglass roving: fiberglass panel roving, spray-up roving, SMC roving, direct roving, c-glass roving, and fiberglass roving for chopping.

|

Product Code

|

Tex

|

Product

Features

|

Resin Compatibility

|

Typical Applications

|

|

362J

|

2400, 4800

|

Excellent choppability and dispersion, good mold

flowability, high mechanical strength of composite

products

|

PU

|

Unit Bathroom |

(Building and Construction / Automotive /Agriculture/Fibreglass Reinforced Polyester)

Fiberglass LFT (Long Fiber Thermoplastic) roving is commonly used in the manufacturing of high-performance composite materials. LFT roving typically consists of continuous glass fibers combined with a thermoplastic polymer matrix. It is widely used in various industries and applications, including automotive, aerospace, consumer goods, and construction.

Some common applications of fiberglass LFT roving include:

1. Automotive Components: LFT roving is used to manufacture structural components for automotive applications, such as body panels, underbody shields, front-end modules, and interior trim parts. Its high strength and impact resistance make it suitable for these demanding applications.

2. Aerospace Parts: LFT roving is utilized in the production of lightweight and strong composite parts for aircraft and aerospace applications. These parts may include interior components, structural elements, and other components that require a balance of strength and weight savings.

3. Sporting Goods: Fiberglass LFT roving is used in the manufacturing of sporting goods such as skis, snowboards, hockey sticks, and bicycle components. Its high strength-to-weight ratio makes it ideal for producing durable and high-performance sports equipment.

4. Industrial Equipment: Components for industrial equipment and machinery, such as machine enclosures, equipment housings, and conveyor systems, can be manufactured using LFT roving due to its strength, impact resistance, and dimensional stability.

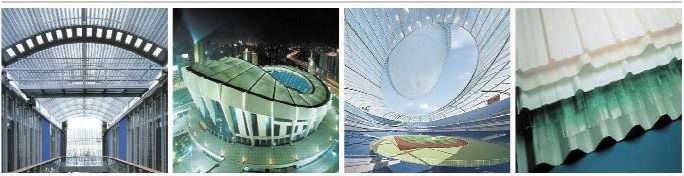

5. Infrastructure and Construction: LFT roving is utilized in applications related to infrastructure and construction, including bridge components, utility enclosures, building facades, and other structural elements that require durability and resistance to environmental factors.

6. Consumer Goods: Various consumer products, such as furniture, appliances, and electronic enclosures, benefit from the use of LFT roving to achieve high strength, impact resistance, and aesthetic appeal.

Overall, fiberglass LFT roving offers a versatile and reliable solution for manufacturing high-strength, lightweight, and durable composite components across a wide range of industries and applications.

Are you in search of high-quality Fiberglass panel roving? Look no further! Our Fiberglass panel roving is specially designed for enhanced panel production, offering exceptional strength and reliability. With its excellent wet-out properties, it ensures optimal resin distribution, resulting in superior panel surface quality. Our Fiberglass panel roving is ideal for various applications, including automotive, aerospace, and building construction. So, if you're in need of top-notch Fiberglass panel roving, contact us today for more details and find the perfect solution for your panel production needs.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.