Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

• Excellent processing properties, low fuzz.

• Multi-resin compatibility.

• Fast and complete wet-out.

• Good mechanical properties of finished parts.

• Excellent chemical corrosion resistance.

Looking for a reliable source of Fiberglass direct roving? Look no further! Our Fiberglass direct roving is manufactured using advanced technology and high-quality materials, ensuring exceptional performance and durability. Designed for a wide range of applications, our Fiberglass direct roving offers excellent wet-out properties, enabling optimal resin impregnation for enhanced strength and rigidity. Whether you need it for composites manufacturing, pultrusion, filament winding, or other applications, our Fiberglass direct roving is the perfect choice. Contact us today to learn more about our Fiberglass direct roving and discover how it can elevate your production process to new heights.

• Direct roving is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven rovings converted from it are used in boats and chemical storage tanks.

We have many types of fiberglass roving: panel roving, spray up roving, SMC roving, direct roving,c glass roving, and fiberglass roving for chopping.

|

Glass Type |

E6-fiberglass direct roving |

||||||||

|

Type of Size |

Silane |

||||||||

|

Size Code |

386T |

||||||||

|

Linear Density (tex) |

300 |

200 400 |

200 600 |

735 900 |

1100 1200 |

2000 |

2200 |

2400 4800 |

9600 |

|

Filament Diameter (μm) |

13 |

16 |

17 |

17 |

17 |

21 |

22 |

24 |

31 |

| Linear Density (%) | Moisture Content (%) | Size Content (%) | Breakage Strength (N/Tex ) |

| ISO 1889 | ISO3344 | ISO1887 | ISO3341 |

| ± 5 | ≤ 0.10 | 0.60 ± 0.10 | ≥0.40(≤2400tex)≥0.35(2401~4800tex)≥0.30(>4800tex) |

| Mechanical Properties |

Unit |

Value |

Resin |

Method |

| Tensile Strength |

MPa |

2660 |

UP |

ASTM D2343 |

| Tensile Modulus |

MPa |

80218 |

UP |

ASTM D2343 |

| Shear strength |

MPa |

2580 |

EP |

ASTM D2343 |

| Tensile Modulus |

MPa |

80124 |

EP |

ASTM D2343 |

| Shear strength |

MPa |

68 |

EP |

ASTM D2344 |

| Shear strength retention (72 hr boiling) |

% |

94 |

EP |

/ |

Memo: The above data are actual experimental values for E6DR24-2400-386H and for reference only

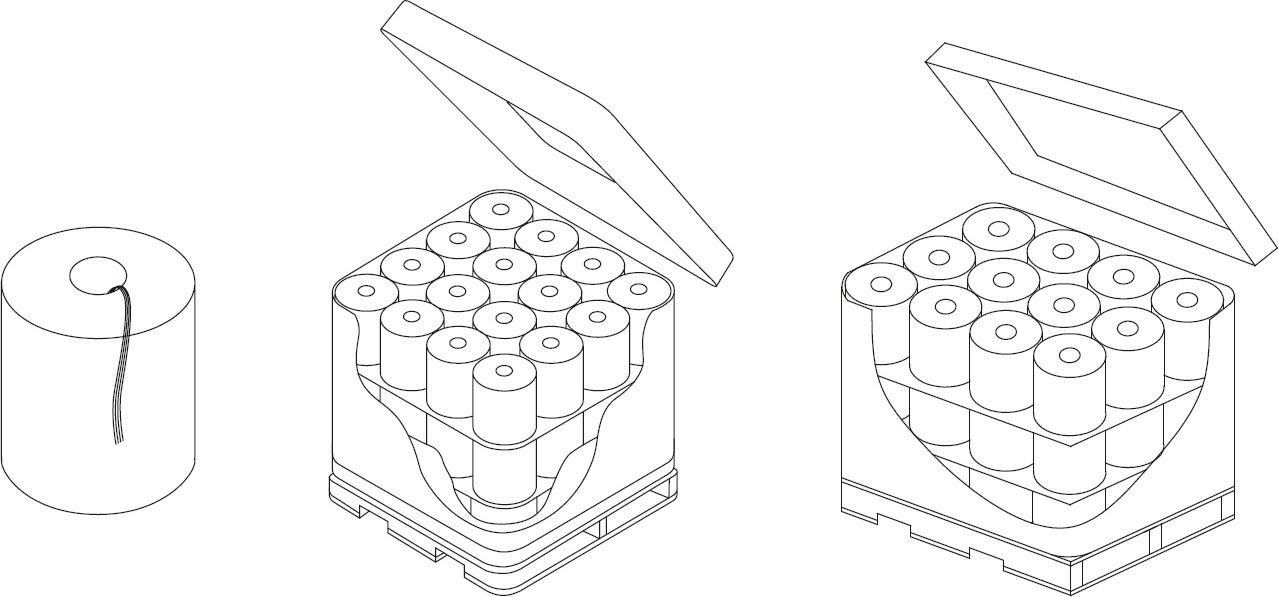

| Package height mm (in) | 255 (10) | 255 (10) |

| Package inside diameter mm (in) | 160 (6.3) | 160 (6.3) |

| Package outside diameter mm (in) | 280 (11) | 310 (12.2) |

| Package weight kg (lb) | 15.6 (34.4) | 22 (48.5) |

| Number of layers | 3 | 4 | 3 | 4 |

| Number of doffs per layer | 16 | 12 | ||

| Number of doffs per pallet | 48 | 64 | 36 | 48 |

| Net weight per pallet kg (lb) | 750 (1653.5) | 1000 (2204.6) | 792 (1746.1) | 1056 (2328.1) |

| Fiberglass direct roving Pallet length mm (in) | 1120 (44.1) | 1270 (50.0) | ||

| Fiberglass direct roving Pallet width mm (in) | 1120 (44.1) | 960 (37.8) | ||

| Fiberglass direct roving Pallet height mm (in) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

• Unless otherwise specified, the fiberglass products should be stored in a dry, cool, and moisture-proof area.

• The fiberglass products should remain in the fiberglass direct roving original package until prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively.

• To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high.

• When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.