Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

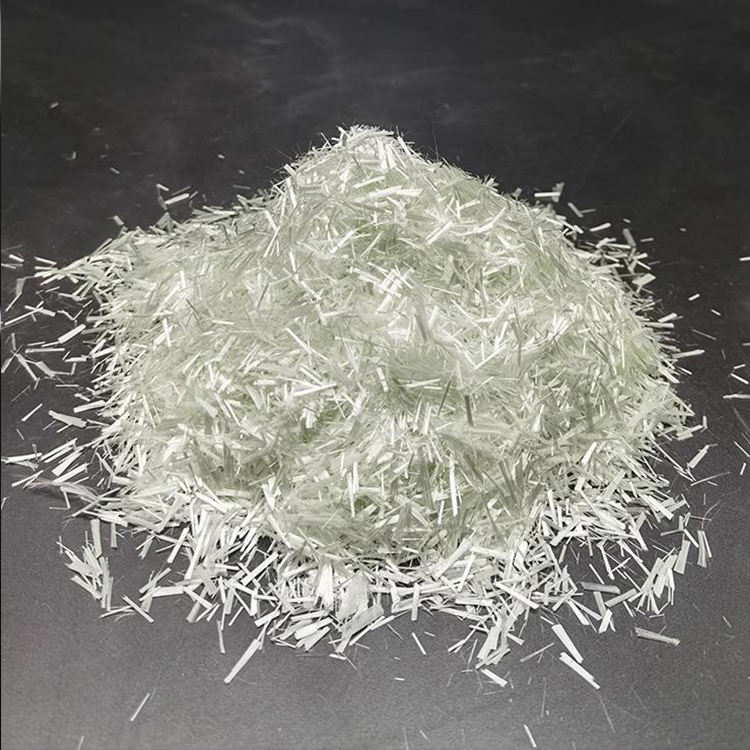

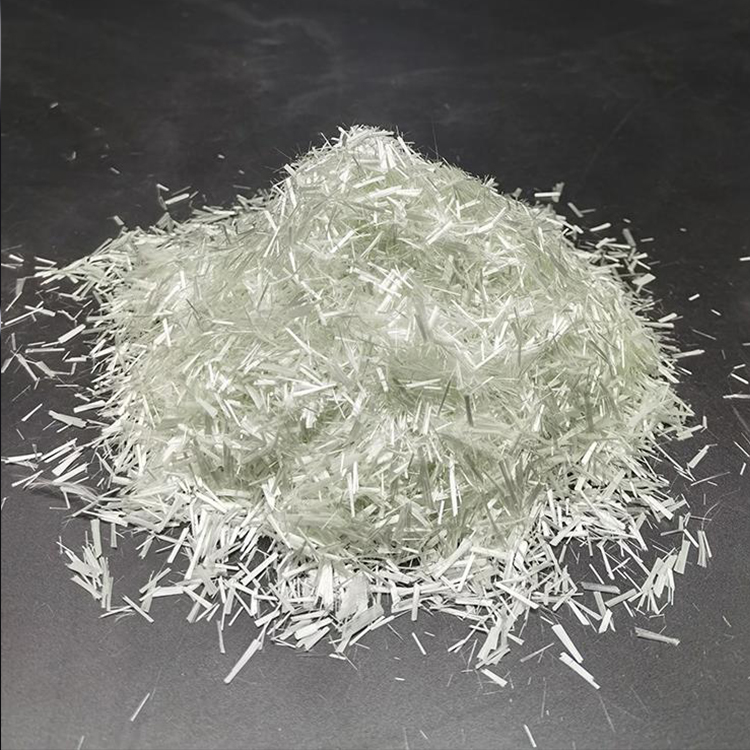

The properties of chopped strands depend on the type of fiber used and the specific application. However, some general properties of chopped strands include:

1. High strength: Chopped strands provide reinforcement to the composite material, increasing its overall strength and load-bearing capacity.

2. Improved impact resistance: The addition of chopped strands can enhance the impact resistance of the composite material, making it more durable and less prone to damage.

3. Enhanced stiffness: Chopped strands can increase the stiffness of the composite, making it more rigid and less prone to deformation under load.

4. Good adhesion: Chopped strands are designed to have good adhesion to the resin matrix, ensuring that the reinforcement is effectively distributed throughout the composite material.

5. Chemical resistance: Depending on the type of fiber used, chopped strands can provide resistance to various chemicals, making the composite material suitable for different environmental conditions.

6. Thermal properties: Chopped strands can also contribute to the thermal properties of the composite, providing insulation or heat resistance as needed.

These properties make chopped strands a versatile and valuable reinforcement material for a wide range of composite applications.

Chopped strands are used in a variety of applications where reinforcement of composite materials is required. Some common applications include:

1. Automotive components: Chopped strands are used in the manufacturing of automotive parts such as bumpers, body panels, and interior components to improve strength, impact resistance, and overall performance.

2. Construction materials: Chopped strands are incorporated into construction materials such as fiberglass-reinforced concrete, insulation, and roofing materials to enhance durability and structural integrity.

3. Consumer products: Chopped strands are utilized in the production of consumer goods such as sporting equipment, furniture, and appliances to improve strength, stiffness, and impact resistance.

4. Marine industry: Chopped strands are used in the fabrication of boat hulls, decks, and other marine components to provide strength, corrosion resistance, and lightweight properties.

5. Aerospace and aviation: Chopped strands are employed in the manufacturing of aircraft components, including interior panels, fairings, and structural parts, to enhance strength-to-weight ratio and performance.

6. Wind energy: Chopped strands are utilized in the production of wind turbine blades to improve their structural integrity and resistance to environmental factors.

These applications demonstrate the versatility and importance of chopped strands in various industries where composite materials are used.

The storage of chopped strands is an important consideration to maintain their quality and performance. Here are some guidelines for the storage of chopped strands:

1. Dry environment: Chopped strands should be stored in a dry environment to prevent moisture absorption, which can lead to degradation of the fibers and affect their performance in composite materials.

2. Controlled temperature: It is advisable to store chopped strands in a controlled temperature environment to prevent exposure to extreme heat or cold, which can impact the properties of the fibers.

3. Protection from contaminants: Chopped strands should be stored in a clean area to avoid contamination from dust, dirt, or other particles that could affect the quality of the fibers.

4. Proper packaging: Chopped strands should be stored in their original packaging or in sealed containers to protect them from exposure to air and other environmental factors.

5. Handling precautions: When handling chopped strands, it is important to use proper protective equipment to avoid damage to the fibers and to maintain their integrity.

By following these storage guidelines, the quality and performance of chopped strands can be preserved, ensuring their effectiveness as reinforcement materials in composite applications.

Dry powder materials can build up static charges, Proper precautions must be taken in the presence of flammable liquids

Fiberglass Chopped Strands can cause eye irritation, harmful if inhaled, may cause skin irritation, harmful if swallowed.Avoid contact with eyes, and contact with skin, Wear goggles and face shield when handing. Always wear an approved respirator. Use only with adequate ventilation. Keep away from heat. Spark and flame. Store handle and use in a manner that minimizes dust generation

In case of contact with skin, wash with warm water and soap. For eyes immediately flush with water for 15 minutes. If irritation continues seek medical attention. If inhaled, move to a fresh air environment. If you have breathing difficulties seek immediate medical attention

Container may be hazardous when empty—empty containers container product residue.

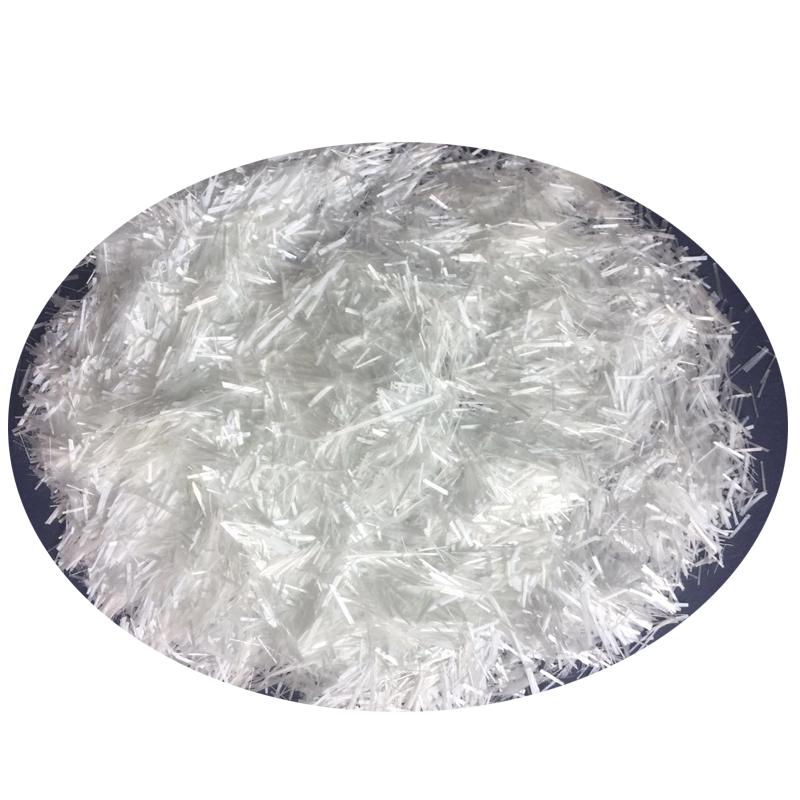

Key Technical Data:

| CS | Glass Type | Chopped Length(mm) | Diameter(um) | MOL(%) |

| CS3 | E-glass | 3 | 7-13 | 10-20±0.2 |

| CS4.5 | E-glass | 4.5 | 7-13 | 10-20±0.2 |

| CS6 | E-glass | 6 | 7-13 | 10-20±0.2 |

| CS9 | E-glass | 9 | 7-13 | 10-20±0.2 |

| CS12 | E-glass | 12 | 7-13 | 10-20±0.2 |

| CS25 | E-glass | 25 | 7-13 | 10-20±0.2 |

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.