Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

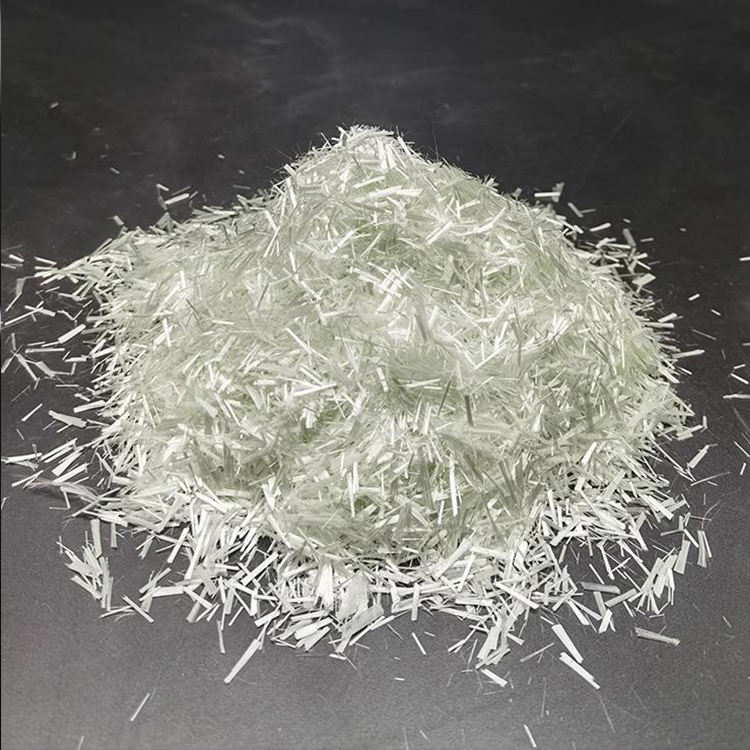

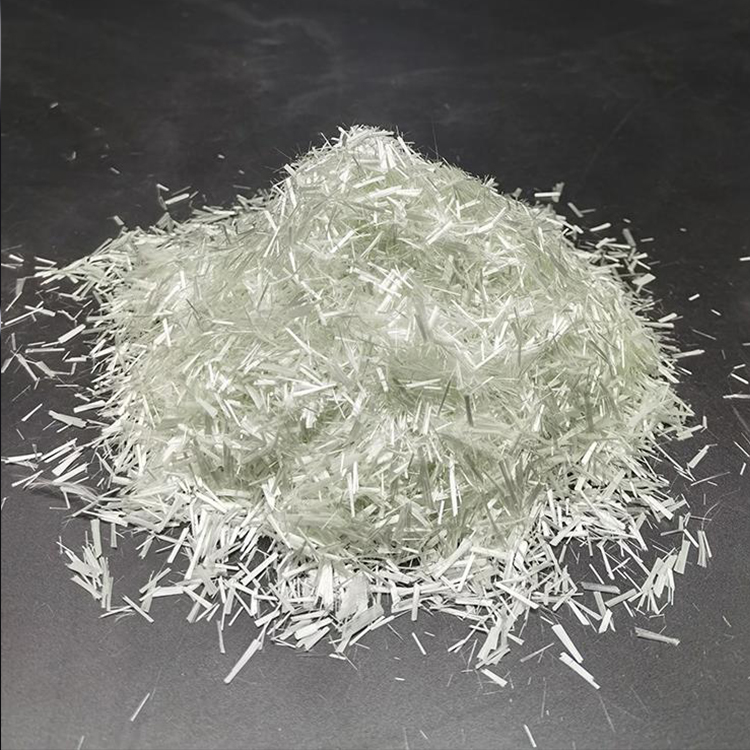

Fiberglass chopped strands have several properties and characteristics. Some of the key properties include:

High Strength: Fiberglass chopped strands provide high tensile strength and stiffness to the composite materials they reinforce.

Chemical Resistance: They offer good resistance to chemicals, corrosion, and environmental degradation when incorporated into composite materials.

Thermal Stability: Fiberglass chopped strands exhibit high-temperature resistance and can maintain their properties at elevated temperatures.

Electrical Insulation: They provide excellent electrical insulation properties, making them suitable for applications in electrical and electronic components.

Lightweight: Fiberglass chopped strands are lightweight, contributing to the overall low weight and high strength of composite materials.

Dimensional Stability: They help improve the dimensional stability and creep resistance of the composite materials they reinforce.

Compatibility: Chopped strands are designed to be compatible with various resin systems, ensuring good adhesion and overall composite performance.

These properties make fiberglass chopped strands versatile and valuable for a wide range of applications in industries such as automotive, construction, aerospace, marine, and more.

Fiberglass chopped strands are commonly used in the manufacturing of a wide range of composite materials. They are utilized in various industries including automotive, aerospace, marine, construction, and consumer goods. Some specific applications of fiberglass chopped strands include:

Automotive Components: Fiberglass chopped strands are used in making components such as bumpers, body panels, and interior parts for vehicles, where their high strength and lightweight properties are valued.

Aerospace Structures: They are used in producing aircraft components due to their strength, stiffness, and resistance to heat and chemicals.

Marine Industry: Fiberglass chopped strands are often utilized in the construction of boat hulls, decks, and other marine components due to their resistance to water and corrosion.

Construction Materials: They are used in producing various construction materials such as pipes, panels, and reinforcements due to their durability and weather-resistant properties.

Consumer Goods: Fiberglass chopped strands are also used in consumer goods such as sports equipment, furniture, and electronic enclosures due to their strength and cost-effectiveness.

Overall, fiberglass chopped strands are versatile materials that are widely used in the production of composite materials to enhance their mechanical and physical properties for various applications.

Fiberglass chopped strands should be stored in dry conditions and the covering membrane should not be opened until they are ready for application.

Dry powder materials have the potential to accumulate static charges, so it is important to take necessary precautions when handling flammable liquids.

Fiberglass Chopped Strands have the potential to cause eye and skin irritation, as well as harmful effects if inhaled or swallowed. It is important to avoid contact with the eyes and skin and to wear goggles, face shield, and an approved respirator when handling this material. Additionally, ensure proper ventilation, avoid exposure to heat, sparks, and flames, and handle and store the material in a way that minimizes dust generation.

If the substance comes into contact with the skin, rinse with warm water and soap. If it gets into the eyes, flush with water for 15 minutes. If irritation persists, seek medical help. If inhaled, move to an area with fresh air, and seek immediate medical attention if experiencing difficulty breathing.

Empty containers may still be hazardous due to product residue.

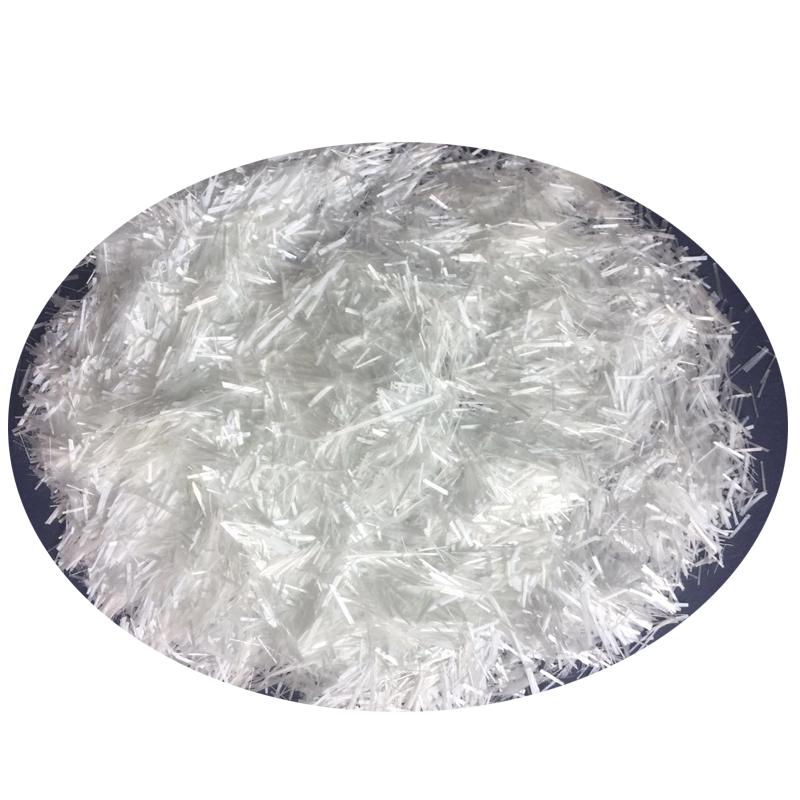

Key Technical Data:

| CS | Glass Type | Chopped Length(mm) | Diameter(um) | MOL(%) |

| CS3 | E-glass | 3 | 7-13 | 10-20±0.2 |

| CS4.5 | E-glass | 4.5 | 7-13 | 10-20±0.2 |

| CS6 | E-glass | 6 | 7-13 | 10-20±0.2 |

| CS9 | E-glass | 9 | 7-13 | 10-20±0.2 |

| CS12 | E-glass | 12 | 7-13 | 10-20±0.2 |

| CS25 | E-glass | 25 | 7-13 | 10-20±0.2 |

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.