Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

• Outstanding processing characteristics with minimal fuzz.

• Compatible with multiple resins.

• Rapid and thorough impregnation.

• High mechanical properties in the final parts.

• Exceptional resistance to chemical corrosion.

Looking for a reliable fiberglass direct roving supplier? Your search ends here! Our fiberglass direct rovings are manufactured using cutting-edge technology and best-in-class materials, guaranteeing superior performance and longevity. Our fiberglass direct rovings are tailored for a variety of uses and have excellent wet-out properties to aid in optimal resin impregnation for increased strength and stiffness. Whether for composite manufacturing, pultrusion, filament winding, or other applications, our fiberglass direct rovings are ideal. Contact us today to discover our fiberglass direct rovings and unlock their potential to enhance your production processes.

Direct roving is applicable for pipes, pressure vessels, gratings, and profiles, while the woven rovings derived from it are utilized in boats and chemical storage tanks. Our range of fiberglass roving encompasses various types, including panel roving, spray-up roving, SMC roving, direct roving, c-glass roving, and fiberglass roving for chopping.

|

Glass Type |

E6-fiberglass direct roving |

||||||||

|

Type of Size |

Silane |

||||||||

|

Size Code |

386T |

||||||||

|

Linear Density (tex) |

300 |

200 400 |

200 600 |

735 900 |

1100 1200 |

2000 |

2200 |

2400 4800 |

9600 |

|

Filament Diameter (μm) |

13 |

16 |

17 |

17 |

17 |

21 |

22 |

24 |

31 |

| Linear Density (%) | Moisture Content (%) | Size Content (%) | Breakage Strength (N/Tex ) |

| ISO 1889 | ISO3344 | ISO1887 | ISO3341 |

| ± 5 | ≤ 0.10 | 0.60 ± 0.10 | ≥0.40(≤2400tex)≥0.35(2401~4800tex)≥0.30(>4800tex) |

| Mechanical Properties |

Unit |

Value |

Resin |

Method |

| Tensile Strength |

MPa |

2660 |

UP |

ASTM D2343 |

| Tensile Modulus |

MPa |

80218 |

UP |

ASTM D2343 |

| Shear strength |

MPa |

2580 |

EP |

ASTM D2343 |

| Tensile Modulus |

MPa |

80124 |

EP |

ASTM D2343 |

| Shear strength |

MPa |

68 |

EP |

ASTM D2344 |

| Shear strength retention (72 hr boiling) |

% |

94 |

EP |

/ |

Memo: The above data are actual experimental values for E6DR24-2400-386H and for reference only

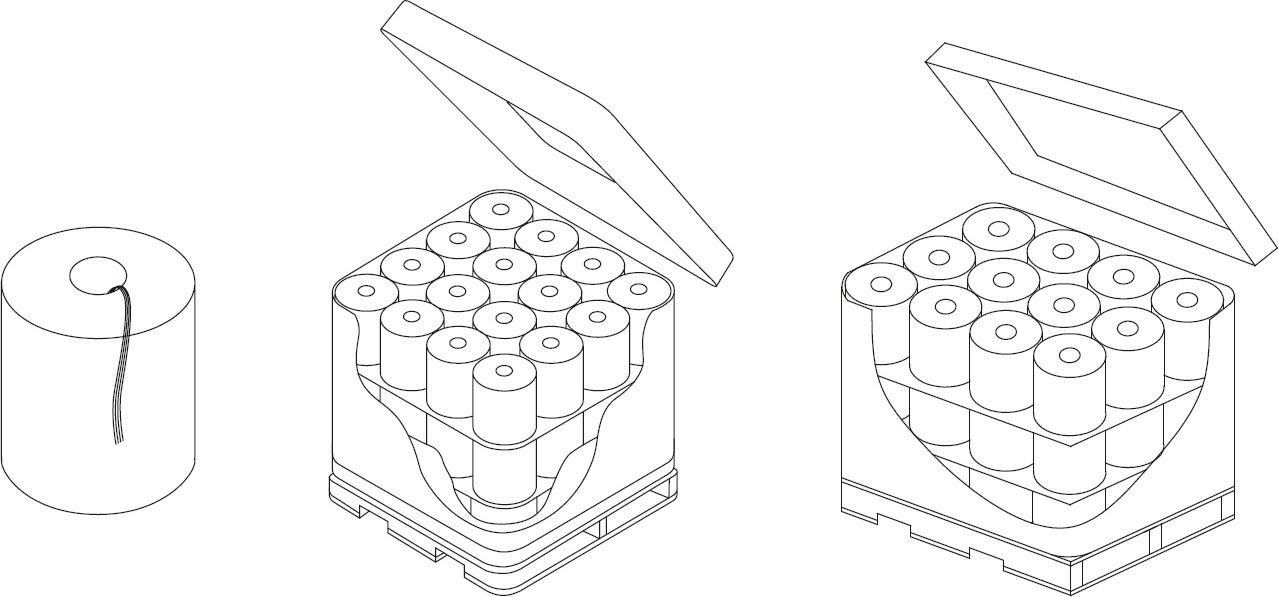

| Package height mm (in) | 255 (10) | 255 (10) |

| Package inside diameter mm (in) | 160 (6.3) | 160 (6.3) |

| Package outside diameter mm (in) | 280 (11) | 310 (12.2) |

| Package weight kg (lb) | 15.6 (34.4) | 22 (48.5) |

| Number of layers | 3 | 4 | 3 | 4 |

| Number of doffs per layer | 16 | 12 | ||

| Number of doffs per pallet | 48 | 64 | 36 | 48 |

| Net weight per pallet kg (lb) | 750 (1653.5) | 1000 (2204.6) | 792 (1746.1) | 1056 (2328.1) |

| Fiberglass direct roving Pallet length mm (in) | 1120 (44.1) | 1270 (50.0) | ||

| Fiberglass direct roving Pallet width mm (in) | 1120 (44.1) | 960 (37.8) | ||

| Fiberglass direct roving Pallet height mm (in) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

• If not specified otherwise, it is recommended to store fiberglass products in a dry, cool, and moisture-proof environment.

• Fiberglass products should be kept in their original packaging until just before use. The room temperature and humidity should be maintained at -10℃~35℃ and ≤80%, respectively.

• To prevent damage and ensure safety, avoid stacking pallets more than three layers high.

• When stacking pallets in 2 or 3 layers, take special care to move the top pallet correctly and smoothly.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.