Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Chongqing Dujiang Composites Co., Ltd. A fibreglass manufacturer of chopped fiberglass mat、fiberglass roving、fiberglass mesh、fiberglass woven roving and so on. is one of good fiberglass material suppliers. We have a fiberglass factory located in Sichuan. Among the many excellent glass fiber manufacturers, there are only a few fiberglass roving manufacturers that are really doing well, CQDJ is one of them.We are not only fiber raw material supplier, but also supplier fiberglass.We have been doing fiberglass wholesale for more than 40 years.We are very familiar with fiberglass manufacturers and fibreglass suppliers all over China.

Woven Roving Combination Mat is a new type of fiberglass mat, it is made by Chopped strand mat and woven roving. The chopped strands layer is from 100g/㎡-900g/㎡, woven roving can be from 300g/㎡–1500g/㎡. It is suitable for Polyester resin, VinyI resin, Epoxy resin, and Phenolic resin. It is mainly used in the boat, car panel, automotive and structural sections.

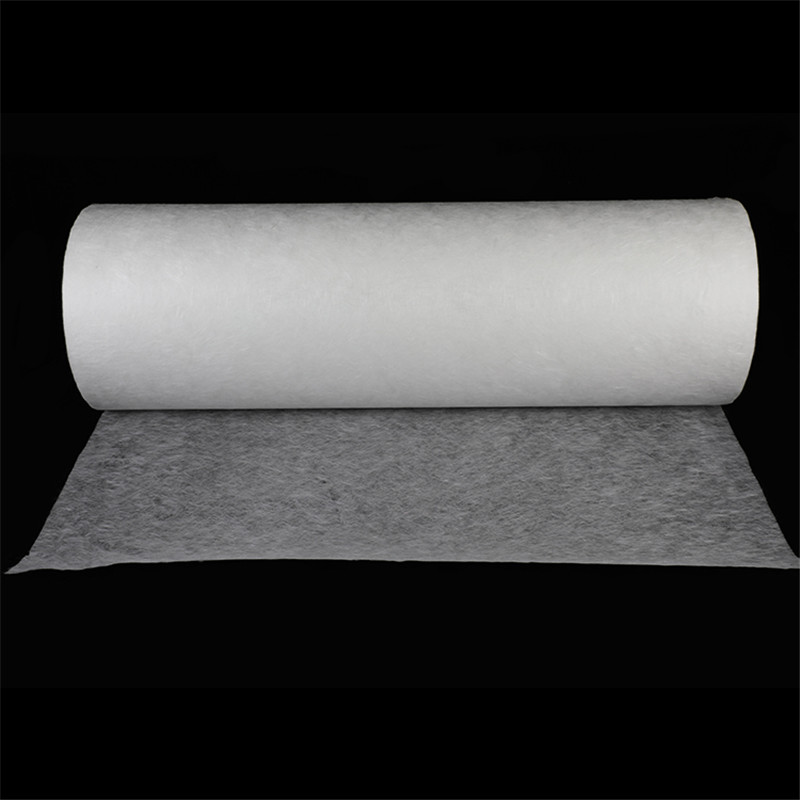

E-Glass Chopped Strand Mat is made of Alkali-free Fiberglass Chopped Strands, which are randomly distributed and bonded together with a polyester binder in powder or emulsion form. The mats are compatible with unsaturated polyester, vinyl ester, and other various resins. It’s mainly used in hand lay-up, filament winding, and compression molding processes. The typical FRP products are panels, tanks, boats, pipes, cooling towers, automobile interior ceilings, a complete set of sanitary equipment, etc.

MOQ:10 tons

E-Glass Chopped Strand Mat is made of Alkali-free Fiberglass Chopped Strands, which are randomly distributed and bonded together with a polyester binder in powder or emulsion form. The mats are compatible with unsaturated polyester, vinyl ester, and other various resins. It’s mainly used in hand lay-up, filament winding, and compression molding processes. The typical FRP products are panels, tanks, boats, pipes, cooling towers, automobile interior ceilings, a complete set of sanitary equipment, etc.

MOQ:10 tons

Fiberglass surface mat: The unique production process of fiberglass surface mat determines that the surface fiber has the characteristics of flatness, uniform dispersion, good hand feeling, and strong air permeability.

The surface mat has the characteristics of fast resin infiltration. The surface mat is used in fiberglass reinforced plastic products, and its good air permeability enables the resin to penetrate quickly, completely eliminates bubbles and white stains, and its good moldability is suitable for any complex shape. , Can cover up the cloth texture, improve the surface finish and anti-leakage performance, at the same time enhance the interlaminar shear strength and surface roughness, and improve the corrosion resistance and weather resistance of the product is a necessity for manufacturing high-quality FRP molds and products. The product is suitable for FRP hand lay-up molding, winding molding, pultrusion profiles, continuous flat plates, vacuum adsorption molding, and other processes.

MOQ:10 tons

PP Core Combination Mat is a new type of fiber glass fabric, it is made by chopped strand mat, Non-woven PP Core fabric woven roving, and other difference layer materials. It is suitable for Polyester resin, VinyI resin, Epoxy resin, and Phenolic resin. It is mainly used in the RTM process, to manufacture the automotive, train parts.

Stitch Chopped Strand Mat is a new type of fiberglass fabric, it is stitched by 50mm Chopped strands cut from CSM roving. The density can be from 200g/㎡ to 900g/㎡ , width from 50mm to 3100mm. This fabric is suitable for Polyester resin, Epoxy resin, Vinyl resin, and Phenolic resin. It is mainly used in the Pultrusion section, pipe lining, FRP boat, and insulation panel for the Hand-lay-up and RTM process.

Surface Veil Stitched Combo Mat is one layer of the surface veil (fiberglass veil or polyester veil) combined with various fiberglass fabrics, multiaxial, and chopped roving layers by stitching them together. The base material can be only one layerorseverallayers of different combinations. It can be mainly applied in pultrusion, resin transfer molding, continuous board making, and other forming processes.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.