Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

In the world of composite materials, fiberglass roving stands out as a versatile and essential component for a wide range of applications. Whether you’re in the automotive, marine, construction, or aerospace industries, our premium fiberglass roving is designed to meet your needs with unparalleled strength, durability, and performance.

High Strength-to-Weight Ratio: Our fiberglass roving boasts an impressive strength-to-weight ratio, making it an ideal choice for applications where weight savings are crucial without compromising on strength. This feature is particularly beneficial in industries like aerospace and automotive, where every ounce counts.

Corrosion Resistance: Unlike traditional materials, fiberglass roving is resistant to a wide range of chemicals and environmental factors. This makes it perfect for marine applications, where exposure to saltwater and harsh weather conditions can lead to material degradation.

Versatility: Our fiberglass roving can be used in various forms, including woven fabrics, mats, and chopped strands. This versatility allows for easy integration into different manufacturing processes, whether you’re creating composite parts, laminates, or reinforced structures.

Easy to Work With The continuous strands of our fiberglass roving can be easily cut, shaped, and molded to fit your specific project requirements. This ease of use reduces production time and labor costs, making it a cost-effective solution for manufacturers.

Thermal Stability: Our fiberglass roving can withstand high temperatures without losing structural integrity. This thermal stability makes it suitable for applications in industries that require materials to perform under extreme conditions.

Eco-Friendly Option: Our fiberglass roving offers an eco-friendly alternative to traditional materials as industries move towards more sustainable practices. It is recyclable and can be repurposed, reducing waste and environmental impact.

Our fiberglass roving is ideal for a multitude of applications, including:

1. Automotive Components: Used in the production of lightweight, high-strength parts that enhance fuel efficiency and performance.

2. Marine Craft: Perfect for boat hulls, decks, and other components that require durability and resistance to water damage.

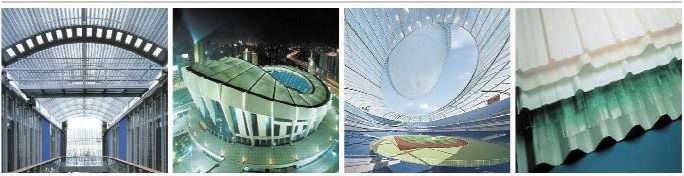

3. Construction Materials: Employed in the reinforcement of concrete, roofing, and other structural elements to improve longevity and safety.

4. Aerospace Engineering: Utilized in the manufacturing of aircraft components that demand high strength and low weight.

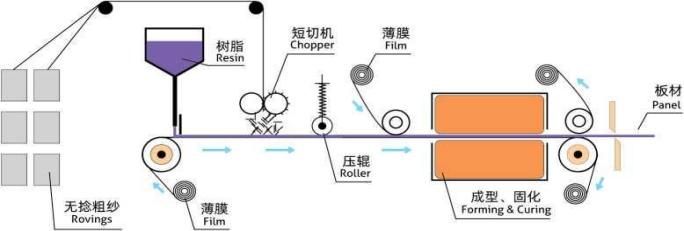

The resin mix is evenly applied in a controlled quantity onto a continuously moving film at a consistent speed. A draw knife regulates the thickness of the resin. Chopped fiberglass roving is then evenly spread over the resin, and a top film is added to create a sandwich structure. The wet assembly is then passed through a curing oven to produce the composite panel.

It seems like you are providing information about different types of fiberglass roving. Is there anything specific you would like to know about these types of roving?

| Model | E3-2400-528s |

| Type of Size | Silane |

| Size Code | E3-2400-528s |

| Linear Density (tex) | 2400TEX |

| Filament Diameter (μm) | 13 |

| Linear Density (%) | Moisture Content | Size Content (%) | Breakage Strength |

| ISO 1889 | ISO3344 | ISO1887 | ISO3375 |

| ± 5 | ≤ 0.15 | 0.55 ± 0. 15 | 120 ± 20 |

(Building and Construction / Automotive /Agriculture/Fibreglass Reinforced Polyester)

• Unless specified otherwise, fiberglass products should be stored in a dry, cool, and moisture-proof area.

• Fiberglass products should be kept in their original packaging until just before use. The room temperature and humidity should be maintained at - 10℃~35℃ and ≤80%, respectively.

• To ensure safety and prevent product damage, pallets should not be stacked more than three layers high.

• When stacking pallets in 2 or 3 layers, special care should be taken to move the top pallets correctly and smoothly.

It seems like you have a promotional message for Fiberglass panel roving. If you have any specific questions or need assistance with refining the message, feel free to ask!

In summary, our premium fiberglass roving is the perfect solution for anyone seeking a reliable, high-performance reinforcement material. With its exceptional strength, versatility, and resistance to environmental factors, it is designed to meet the demands of modern manufacturing across various industries. Whether you’re looking to enhance the durability of your products or reduce weight without sacrificing strength, our fiberglass roving is the answer. Experience the difference today and elevate your projects to new heights with our top-quality fiberglass roving!

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.