Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Fiberglass Smc roving features:

Key characteristics of fiberglass assembled roving include remarkable patentability and fiber whiteness, effective anti-static properties and capability, rapid and thorough wet-out, and exceptional molding fluidity.

Fiberglass sheet molding compound (SMC) roving typically features high tensile strength, excellent impact resistance, good electrical insulation properties, dimensional stability, and corrosion resistance.

It can also have a good surface finish, heat resistance, and flame retardant capabilities.

| Fiberglass assembled roving | ||

| Glass type | E-GLASS | |

| Sizing type | Silane | |

| Typical filament diameter (um) | 14 | |

| Typical linear density (tex) | 2400 | 4800 |

| Example | ER14-4800-442 | |

| Item | Linear density variation | Moisture content | Sizing content | Stiffness |

| Unit | % | % | % | mm |

| Test method | ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| Standard Range | ± 5 | ≤ 0.10 | 1.05 ± 0.15 | 150 ± 20 |

Not only do we produce fiberglass assembled roving and fiberglass mats, but we are also agents of JUSHI.

· The product is best used within 12 months after production and should be kept in the original package before use.

·Care should be taken when using the product to prevent it from being scratched or damaged.

·The temperature and humidity of the product should be conditioned to be close to or equal to the ambient temperature and humidity before use, and the ambient temperature and humidity should be properly controlled during use.

·The cutter rollers and rubber rollers should be maintained regularly.

| Item | unit | Standard | |

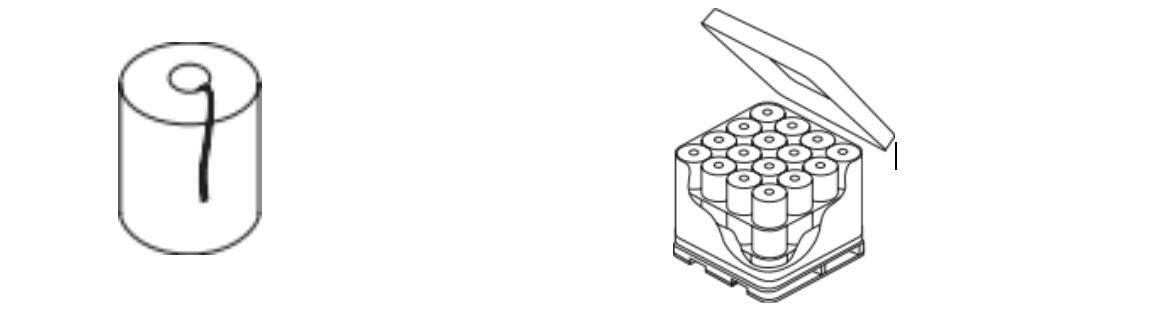

| Typical packaging method | / | Packed on pallets. | |

| Typical package height | mm (in) | 260 (10.2) | |

| Package inner diameter | mm (in) | 100 (3.9) | |

| Typical package outer diameter | mm (in) | 280 (11.0) | |

| Typical package weight | kg (lb) | 17.5 (38.6) | |

| Number of layers | (layer) | 3 | 4 |

| Number of packages per layer | 个 (pcs) | 16 | |

| Number of packages per pallet | 个 (pcs) | 48 | 64 |

| Net weight per pallet | kg (lb) | 840 (1851.9) | 1120 (2469.2) |

| Pallet length | mm (in) | 1140 (44.9) | |

| Pallet width | mm (in) | 1140 (44.9) | |

| Pallet height | mm (in) | 940 (37.0) | 1200 (47.2) |

SMC roving is commonly used in the manufacturing of various components in industries such as automotive, aerospace, construction, and electrical. It is often utilized for producing parts with complex shapes and high strength requirements, such as automotive body panels, electrical enclosures, and structural components in construction. Additionally, SMC roving can be employed in the production of consumer goods, marine products, and other industrial applications that require durable, lightweight, and corrosion-resistant materials.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.