Fiberglass grating has a wide range of applications across various industries due to its excellent properties such as corrosion resistance, lightweight, and high strength. The following are some of the projects our factory has done:

Flooring and Walkways: Used in industrial plants, warehouses, and parking lots for slip-resistant and durable flooring. Indoor and outdoor industrial floor.

Corrosion-Resistant Structures: Ideal for use in chemical plants and wastewater treatment facilities, where it can withstand harsh chemicals and environments.

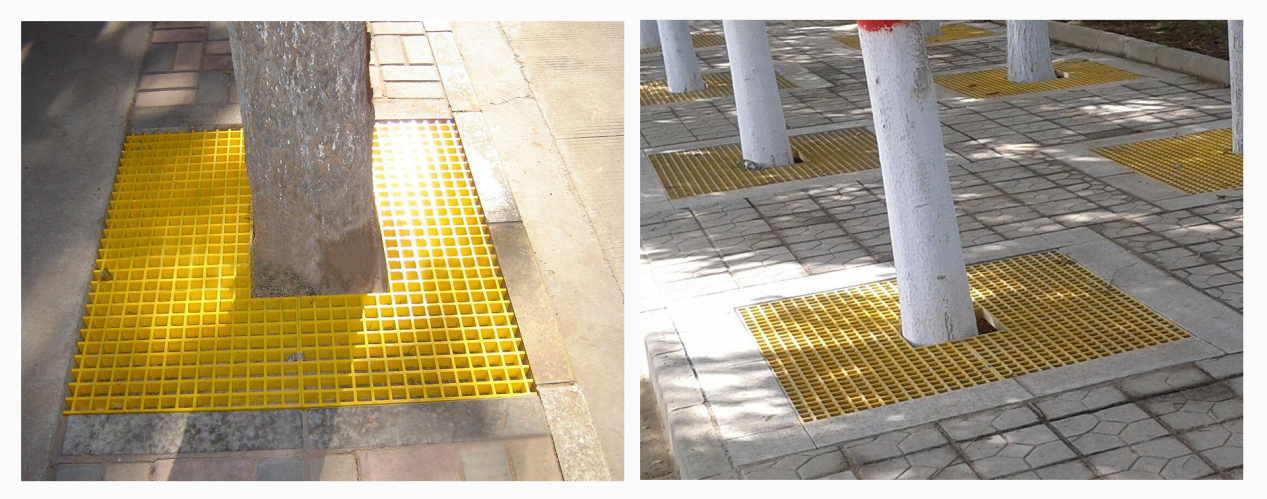

Environment:The use of fiberglass grating in FRP tree holes can improve the stability and durability of the structure while also aiding in the growth of plants.

Overall, fiberglass grating is an essential material in many industrial sectors due to its unique combination of properties, making it a preferred choice for various applications.

Fiberglass grating has several key features that make it a popular choice in various applications:

Corrosion Resistance: Fiberglass grating is highly resistant to chemicals, moisture, and environmental factors, making it ideal for use in corrosive environments such as chemical plants and wastewater treatment facilities.

Lightweight: Compared to traditional materials like steel or aluminum, fiberglass grating is significantly lighter, which simplifies handling, installation, and transportation.

High Strength-to-Weight Ratio: Despite its lightweight nature, fiberglass grating offers excellent strength and load-bearing capabilities, making it suitable for heavy-duty applications.

Slip Resistance: Many fiberglass grating products feature a textured surface that provides excellent slip resistance, enhancing safety in industrial and commercial settings.

Low Maintenance: Fiberglass grating requires minimal maintenance due to its durability and resistance to rot, rust, and UV degradation.

Customizability: Fiberglass grating can be manufactured in various sizes, shapes, and colors, allowing for customization to meet specific project requirements.

Thermal Insulation: Fiberglass has good thermal insulation properties, which can be beneficial in applications where temperature control is important.

Non-Conductive: Fiberglass grating is non-conductive, making it a safe choice for electrical applications and environments where electrical hazards may be present.

These features make fiberglass grating a versatile and effective solution for a wide range of industrial, commercial, and environmental applications.

Fiberglass grating comes in several types, each designed for specific applications and environments. Here are the main types:

Molded Fiberglass Grating:

Description: Made by molding fiberglass resin and reinforcing materials into a solid structure.

Features: Offers high strength, corrosion resistance, and slip resistance. It is available in various thicknesses and panel sizes.

Applications: Commonly used in industrial flooring, walkways, and platforms.

https://www.frp-cqdj.com/fiberglass-molded-grating-suppliers-frp-grp-walkway-product/

Pultruded Fiberglass Grating:

Description: Created by pulling fiberglass through a resin bath and then through a heated die to form a solid shape.

Features: Provides a higher load-bearing capacity compared to molded grating, with a smooth surface finish.

Applications: Suitable for heavy-duty applications, such as in chemical processing plants and oil rigs.

https://www.frp-cqdj.com/fiberglass-pultruded-grating-frp-strongwell-fibergrate-product/

Heavy-Duty Grating:

Description: A thicker and more robust version of molded or pultruded grating.

Features: Designed to support heavier loads and withstand more demanding conditions.

Applications: Often used in areas with heavy machinery or high foot traffic.

Light-Duty Grating:

Description: Thinner and lighter than heavy-duty grating.

Features: Suitable for applications with lower load requirements.

Applications: Used in walkways, platforms, and other areas where weight is a concern.

Architectural Grating:

Description: Designed with aesthetics in mind, often available in various colors and patterns.

Features: Combines functionality with visual appeal.

Applications: Used in commercial buildings, parks, and other public spaces.

Custom Grating:

Description: Tailored to specific project requirements, including size, shape, and load capacity.

Features: Offers flexibility for unique applications.

Applications: Used in specialized environments where standard grating may not suffice.

Each type of fiberglass grating is designed to meet specific needs, making it a versatile choice for various industrial, commercial, and architectural applications.

In addition to gratings, our profile products are rich in variety and cover multiple fields, including fiberglass rods, fiberglass tubes, fiberglass composite bars and fiberglass channels, etc. These products have their own characteristics and can meet the needs of different customers.

Our fiberglass rods are widely used in construction, transportation and sports equipment due to their excellent strength and lightness. They are not only corrosion-resistant, but also have good insulation properties, suitable for use in various harsh environments.

Fiberglass tubes are one of our highlights. With their excellent chemical resistance and high temperature resistance, they have been exported to dozens of countries around the world and won the trust and cooperation of thousands of customers. These pipes play an important role in agricultural irrigation, chemical transportation and building drainage, ensuring the safe and efficient transmission of fluids.

Our fiberglass composite bars are ideal reinforcement materials for concrete structures. They can effectively improve the tensile strength and durability of buildings and are widely used in engineering projects such as bridges, tunnels and high-rise buildings.

In addition, fiberglass channels are suitable for supporting structures of various industrial equipment with their excellent load-bearing capacity and bending resistance to ensure the stability and safety of the equipment.

Our products are widely used in many fields such as agriculture, construction and industry, helping customers improve production efficiency and product quality. We are always committed to innovation and quality, and strive to provide customers with the best solutions.

Fiberglass Rods

https://www.frp-cqdj.com/flexible-fiberglass-rod-solid-wholesale-product/

Our fiberglass rods are known for their excellent physical properties and chemical stability. They are stronger than many traditional materials and are lightweight, making them easy to handle and install. The corrosion resistance of fiberglass rods has led to their wide application in chemical, construction, and transportation industries. For example, in the construction industry, fiberglass rods are often used to reinforce concrete structures and improve the tensile strength and durability of buildings. In the transportation sector, they are used to make lightweight body parts and improve the fuel efficiency of vehicles.

In addition, fiberglass rods are also widely used in the manufacture of sports equipment, such as ski poles, fishing rods, etc., because of their lightness and high strength, they can provide a better use experience for sports enthusiasts.

Fiberglass tubes

https://www.frp-cqdj.com/fiberglass-tube-fiberglass-pipe-high-strength-product/

Our fiberglass tubes are another important product. With their excellent chemical resistance and high temperature resistance, they have been exported to dozens of countries around the world and have won the trust and cooperation of thousands of customers. These tubes play an important role in agricultural irrigation, chemical transportation and building drainage.

In the agricultural field, fiberglass tubes are widely used in irrigation systems, which can effectively transport water and ensure the healthy growth of crops. Due to its corrosion resistance, fiberglass tubes also perform well in the transportation of fertilizers and pesticides, avoiding leakage and loss caused by corrosion of traditional metal pipes.

In the construction industry, fiberglass tubes are often used in drainage and ventilation systems, which can effectively remove excess moisture and gas, keeping buildings dry and safe. In addition, the lightweight nature of fiberglass tubes makes the installation process easier, saving manpower and time costs.

Glass Fiber Composite Rebar

https://www.frp-cqdj.com/solid-fiberglass-rebar-frp-flexible-product/

Our fiberglass rebar is an ideal reinforcement material for concrete structures, which can effectively improve the tensile strength and durability of buildings. Compared with traditional steel bars, glass fiber composite rebars have better corrosion resistance and lighter weight, and are suitable for various harsh environments.

The application of glass fiber composite rebars is becoming more and more common in engineering projects such as bridges, tunnels and high-rise buildings. They can not only improve the safety of structures, but also extend the service life of buildings and reduce maintenance costs. In addition, the non-conductive properties of glass fiber composite rebars have also made them used in fields such as power facilities and communication towers to ensure safety.

Fiberglass Channel

https://www.frp-cqdj.com/fiberglass-c-channel-grp-structural-shape-product/

Finally, our fiberglass channel is suitable for supporting structures of various industrial equipment with its excellent load-bearing capacity and bending resistance. The lightweight characteristics of fiberglass channel make installation and maintenance more convenient, especially in occasions where equipment needs to be frequently replaced or adjusted.

In the industrial field, fiberglass channel is widely used in manufacturing, chemical plants, and power facilities. They can withstand heavy loads and ensure the stability and safety of equipment. In addition, the corrosion resistance of fiberglass channel makes it perform well in harsh environments and reduces safety hazards caused by material aging.

Advantages of Wide Application

Our fiberglass products are widely used in many fields such as agriculture, construction and industry. Through close cooperation with customers, we continuously optimize product design to meet the needs of different markets. Our goal is to provide customers with high-quality solutions to help them improve production efficiency and product quality.

In agriculture, our products help farmers improve irrigation efficiency and ensure the healthy growth of crops. In the construction industry, our fiberglass materials enhance the safety and durability of buildings and reduce maintenance costs. In the industrial field, our products improve the stability and safety of equipment and ensure the smooth progress of production.

Future Outlook

Looking to the future, we will continue to be committed to technological innovation and product research and development to meet the ever-changing market needs. We believe that with the emphasis on environmental protection and sustainable development, fiberglass materials will be used in more fields. We look forward to working with more customers to jointly promote the development of the industry and achieve a win-win situation.

In short, our fiberglass products are bringing changes to all walks of life with their excellent performance and wide application. Whether in agriculture, construction or industry, we will continue to work hard to provide customers with the best products and services.