Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

As for aggressive rates, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such good quality at such charges we are the lowest around for Manufacturer China Fiberglass Direct Roving 300tex for Fiberglass Mesh, Our closing purpose is “To try the most beneficial, To generally be the Best”. Be sure to sense free of charge to get hold of with us if you have any prerequisites.

As for aggressive rates, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such good quality at such charges we are the lowest around for China Fiberglass Direct Roving and Fiberglass Roving Manufacture, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our goods to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

• Excellent processing properties, low fuzz.

• Multi-resin compatibility.

• Fast and complete wet-out.

• Good mechanical properties of finished parts.

• Excellent chemical corrosion resistance.

• Direct roving is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven rovings converted from it are used in boats and chemical storage tanks.

We have many types of fiberglass roving: panel roving, spray up roving, SMC roving, direct roving,c glass roving, and fiberglass roving for chopping.

|

Glass Type |

E6 |

||||||||

|

Type of Size |

Silane |

||||||||

|

Size Code |

386T |

||||||||

|

Linear Density (tex) |

300 |

200 400 |

200 600 |

735 900 |

1100 1200 |

2000 |

2200 |

2400 4800 |

9600 |

|

Filament Diameter (μm) |

13 |

16 |

17 |

17 |

17 |

21 |

22 |

24 |

31 |

| Linear Density (%) | Moisture Content (%) | Size Content (%) | Breakage Strength (N/Tex ) |

| ISO 1889 | ISO3344 | ISO1887 | ISO3341 |

| ± 5 | ≤ 0.10 | 0.60 ± 0.10 | ≥0.40(≤2400tex)≥0.35(2401~4800tex)≥0.30(>4800tex) |

| Mechanical Properties |

Unit |

Value |

Resin |

Method |

| Tensile Strength |

MPa |

2660 |

UP |

ASTM D2343 |

| Tensile Modulus |

MPa |

80218 |

UP |

ASTM D2343 |

| Shear strength |

MPa |

2580 |

EP |

ASTM D2343 |

| Tensile Modulus |

MPa |

80124 |

EP |

ASTM D2343 |

| Shear strength |

MPa |

68 |

EP |

ASTM D2344 |

| Shear strength retention (72 hr boiling) |

% |

94 |

EP |

/ |

Memo: The above data are actual experimental values for E6DR24-2400-386H and for reference only

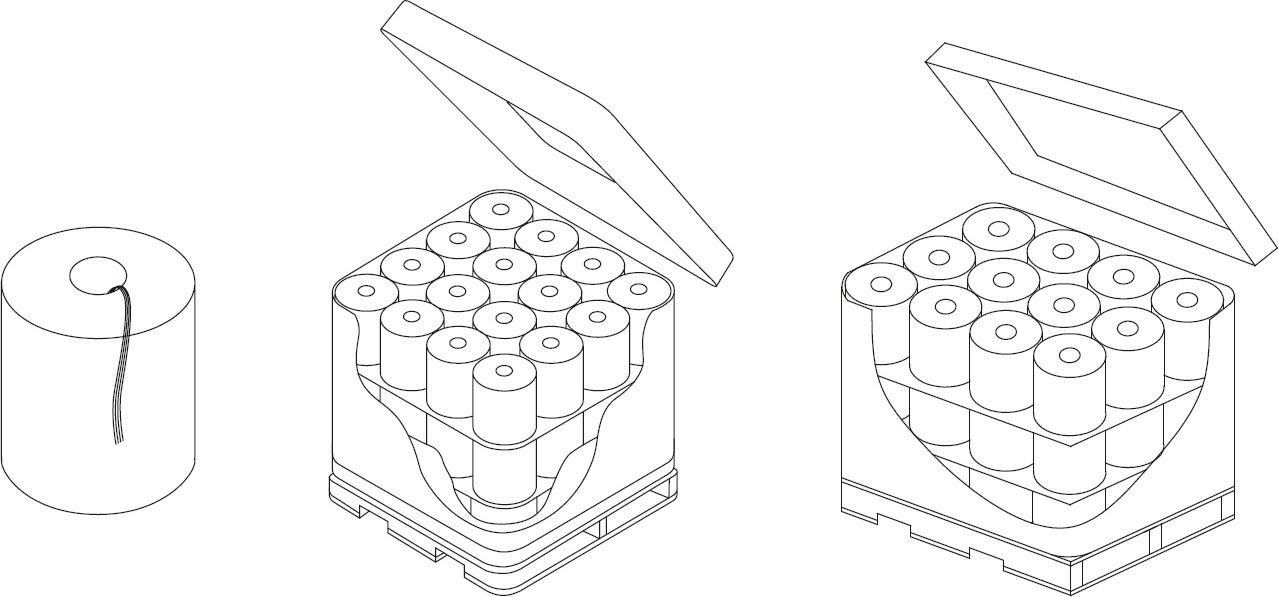

| Package height mm (in) | 255 (10) | 255 (10) |

| Package inside diameter mm (in) | 160 (6.3) | 160 (6.3) |

| Package outside diameter mm (in) | 280 (11) | 310 (12.2) |

| Package weight kg (lb) | 15.6 (34.4) | 22 (48.5) |

| Number of layers | 3 | 4 | 3 | 4 |

| Number of doffs per layer | 16 | 12 | ||

| Number of doffs per pallet | 48 | 64 | 36 | 48 |

| Net weight per pallet kg (lb) | 750 (1653.5) | 1000 (2204.6) | 792 (1746.1) | 1056 (2328.1) |

| Pallet length mm (in) | 1120 (44.1) | 1270 (50.0) | ||

| Pallet width mm (in) | 1120 (44.1) | 960 (37.8) | ||

| Pallet height mm (in) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

• Unless otherwise specified, the fiberglass products should be stored in a dry, cool, and moisture-proof area.

• The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively.

• To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high.

• When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.