Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Massive Selection for China 4800tex E Glass Fiberglass Direct Roving for Producing Rebar, We give priority to high quality and customer fulfillment and for this we follow stringent good quality control measures. We have now in-house testing facilities where our goods are tested on every single aspect at different processing stages. Owning to latest technologies, we facilitate our shoppers with custom made manufacturing facility.

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for China 4800tex Roving, E-Glass Roving, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

·Excellent choppability and dispersion

·Good anti-static property

·Fast and complete wet-out ensures easy roll-out and rapid air release. ·Excellent mechanical properties of composite parts

·Excellent hydrolysis resistance of composite parts

| Glass type | E6 | |||

| Sizing type | Silane | |||

| Typical filament diameter (um) | 11 | 13 | ||

| Typical linear density (tex) | 2400 | 3000 | 4800 | |

| Example | E6R13-2400-180 | |||

| Item | Linear density variation | Moisture content | Size content | Stiffness |

| Unit | % | % | % | mm |

| Test menthod | ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| Standard range | ± 4 | ≤ 0.07 | 1.00 ± 0.15 | 140 ± 20 |

The product is best used within 12 months after production, and should be kept in the original package before use. ·Care should be taken when using the product to prevent it from being scratched or damaged.

·The temperature and humidity of the product should be conditioned to be close or equal to the ambient temperature and humidity before use, and the ambient temperature and humidity should be properly controlled during the use.

| Item | unit | Standard | |||

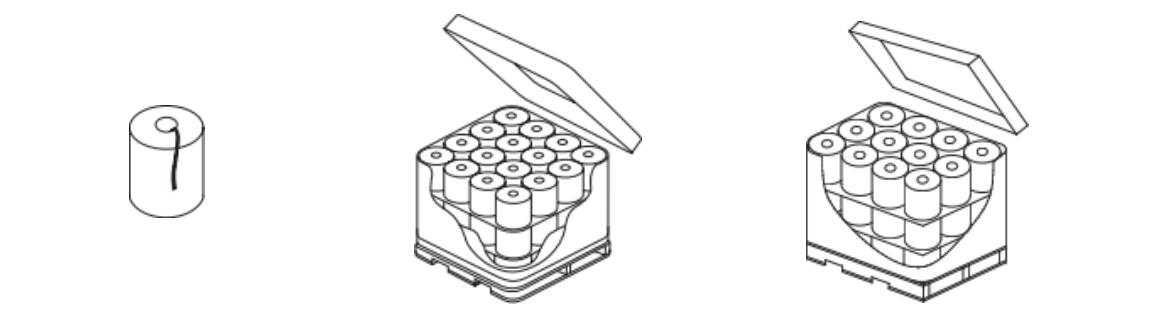

| Typical packaging method | / | Packed on pallets. | |||

| Typical package height | mm (in) | 260 (10.2) | |||

| Package inner diameter | mm (in) | 100 (3.9) | |||

| Typical package outer diameter | mm (in) | 280 (11.0) | 310 (12.2) | ||

| Typical package weight | kg (lb) | 17.5 (37.5) | 23 (50.7) | ||

| Number oflayers | (layer) | 3 | 4 | 3 | 4 |

| Number of packages per layer | 个 (pcs) | 16 | 12 | ||

| Number of packages per pallet | 个 (pcs) | 48 | 64 | 36 | 48 |

| Net weight per pallet | kg (lb) | 840 (1851.9) | 1120 (2469.2) | 828 (1825.4) | 1104 (2433.9) |

| Pallet length | mm (in) | 1140 (44.9) | 1270 (50.0) | ||

| Pallet width | mm (in) | 1140 (44.9) | 960 (37.8) | ||

| Pallet height | mm (in) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture-proof area.The best temperature and humidity should be maintained at -10℃~35℃ and ≤80% respectively. To ensure safety and avoid damage to the product, the pallets should be stacked not more than three layers high. When the pallets are stacked in two or three layers, special care should be taken to correctly and smoothly move the upper pallet.

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Massive Selection for China 4800tex E Glass Fiberglass Direct Roving for Producing Rebar, We give priority to high quality and customer fulfillment and for this, we follow stringent good quality control measures. We now have in-house testing facilities where our goods are tested on every aspect at different processing stages. Owning to latest technologies, we facilitate our shoppers with custom-made manufacturing facilities.

Massive Selection for China 4800tex Roving, E Glass Roving, We confirm to the public, that cooperation, the win-win situation as our principle, adhere to the philosophy of making a living by quality, keep developing by honesty, sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and shared prosperity.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.