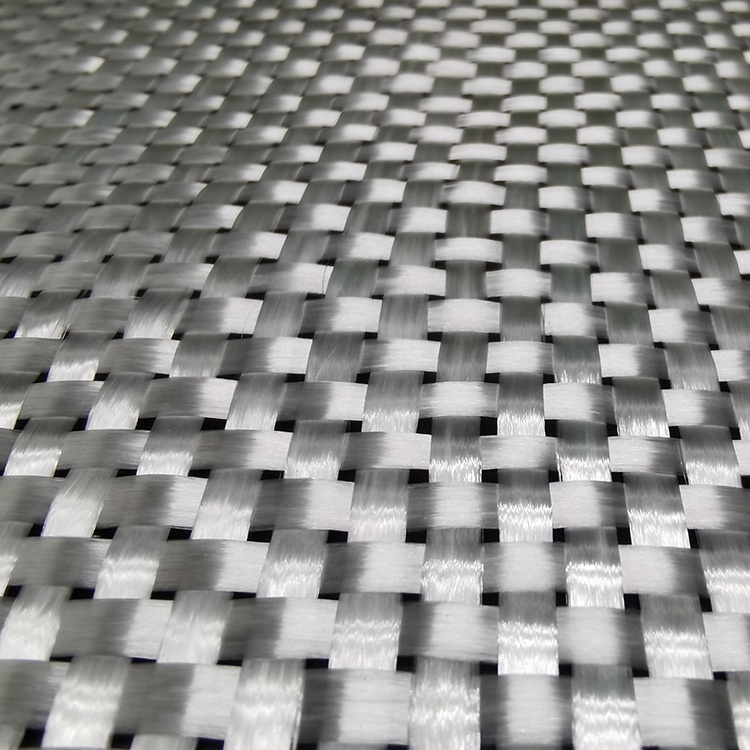

Woven roving is a specific type of woven roving made from E-glass fibers. single-end roving in thick fiber bundles that are woven in a 00/900 (warp and weft) orientation much like standard textiles on a weaving loom. Fiberglass E-glass roving is a specialized reinforcement material crucial in the production of composite materials.

When using E-glass woven roving in composite manufacturing, it is typically impregnated with a resin (such as epoxy) to create a strong and durable composite material.

The production process typically involves the following steps:

Producing woven roving from fiberglass roving involves weaving the continuous roving strands into a fabric with a specific pattern.

Raw Material Preparation:

Start with E-glass fiberglass roving, a bundle of continuous glass filaments without twisting.

The roving is typically coated with a sizing material to improve its compatibility with the resin matrix in the final composite and to protect the filaments during processing.

Warping:

The continuous roving is wound onto warp beams. These beams hold the roving under tension, and the number of strands on each beam determines the width and weight of the final woven roving fabric.

Weaving:

Use weaving machines to interlace the warp (longitudinal) and weft (transverse) strands of roving to form the woven roving fabric.

The weaving pattern is typically a simple over-and-under pattern, creating a square or rectangular grid structure.

Sizing Application (Optional):

Depending on the specific requirements of the application, an additional sizing application may be carried out after weaving to enhance the compatibility of the woven roving with specific resin systems.

Rolling and Inspection:

The woven roving is rolled onto large rolls for ease of handling, transportation, and further processing.

Application

Fiberglass woven roving finds applications in various industries where high strength and reinforcement are required. Some common applications include:

Marine Industry:

Boat Hulls: Fiberglass woven roving is often used to reinforce boat hulls, providing strength and durability to withstand the stresses of marine environments.

Marine Components: It is utilized in the construction of various marine components such as decks, bulkheads, and transoms.

Automotive Industry:

Vehicle Components: Fiberglass woven roving is employed in the manufacturing of automotive components, including body panels, interior parts, and structural elements.

Custom Car Parts: It is used to create custom parts and panels for specialty or high-performance vehicles.

Construction and Infrastructure:

Building Materials: Fiberglass woven roving reinforces construction materials, such as panels, pipes, and tanks, contributing to increased strength and durability.

Infrastructure: It is used in the construction of bridges, tunnels, and other infrastructure components.

Aerospace Industry:

Aircraft Components: Fiberglass woven roving is utilized in the aerospace industry to reinforce components such as fuselage sections, wings, and interior structures.

Spacecraft: It may be used in the construction of certain spacecraft components.

Wind Energy:

Wind Turbine Blades: Fiberglass woven roving is commonly used in the manufacturing of wind turbine blades, providing the necessary strength and rigidity.

Sports and Recreation:

Sporting Goods: Fiberglass woven roving is used in the production of sporting goods such as kayaks, canoes, and other recreational equipment.

Composite Bicycles: It is employed in the construction of lightweight and high-performance bicycle frames.

Industrial Applications:

Tanks and Containers: Fiberglass woven roving is used in the fabrication of tanks and containers for storage and transportation of liquids and chemicals.

Industrial Equipment: It is employed in the reinforcement of various industrial equipment components.

Miscellaneous Applications:

Custom Fabrication: Fiberglass woven roving is often used in custom fabrication projects where a combination of strength and moldability is required.

Art and Sculpture: Artists and sculptors may use fiberglass woven roving for creating strong and lightweight structures.

These applications highlight the versatility of fiberglass woven roving in providing reinforcement and strength to a wide range of products across different industries. The specific choice of woven roving and the manufacturing process may vary based on the requirements of each application.

Our products

Contact Us:

Phone number/WhatsApp:+8615823184699

Email: marketing@frp-cqdj.com

Website: www.frp-cqdj.com

Post time: Jan-16-2024