Fiberglass mesh is a versatile and essential material in the construction and renovation industry. Its unique properties make it suitable for various applications, including concrete reinforcement, plastering, and stucco work. This article explores the different types of fiberglass mesh, such as fiberglass mesh for concrete, fiberglass mesh tape, fiberglass mesh for plastering, and fiberglass mesh for stucco, and discusses their applications in detail.

Understanding Fiberglass Mesh

Fiberglass mesh is made from woven strands of fiberglass, which are known for their strength, durability, and resistance to environmental factors. The mesh is typically coated with a polymer to enhance its properties, making it suitable for various construction applications. The lightweight yet robust nature of fiberglass mesh allows it to be used in a range of projects, from residential renovations to large-scale commercial constructions.

1. Fiberglass Mesh for Concrete

One of the primary applications of fiberglass mesh is in concrete reinforcement. Fiberglass mesh for concrete is designed to enhance the tensile strength of concrete structures, preventing cracking and improving durability. When embedded in concrete, the mesh distributes loads evenly, reducing the risk of structural failure.

Benefits of Using Fiberglass Mesh for Concrete:

Crack Prevention: Fiberglass mesh helps to control cracking in concrete slabs, walls, and other structures, ensuring longevity and stability.

Lightweight: Compared to traditional steel reinforcement, fiberglass mesh is lighter, making it easier to handle and install.

Corrosion Resistance: Unlike steel, fiberglass does not corrode, making it ideal for use in environments exposed to moisture or chemicals.

Cost-Effective: The use of fiberglass mesh can reduce the amount of concrete needed, leading to cost savings in materials and labor.

2.Fiberglass Mesh Tape

Fiberglass mesh tape is another important application of fiberglass mesh, primarily used for drywall and joint reinforcement. This tape is designed to provide a strong bond between drywall seams, preventing cracks and ensuring a smooth finish.

Applications of Fiberglass Mesh Tape:

Drywall Installation: When applied to joints between drywall sheets, fiberglass mesh tape reinforces the seams, making them less prone to cracking.

Repair Work: Fiberglass mesh tape is ideal for repairing damaged drywall, as it can be easily applied over cracks and holes, providing a strong foundation for joint compound.

Moisture Resistance: Some fiberglass mesh tapes are designed to be moisture-resistant, making them suitable for use in bathrooms and kitchens.

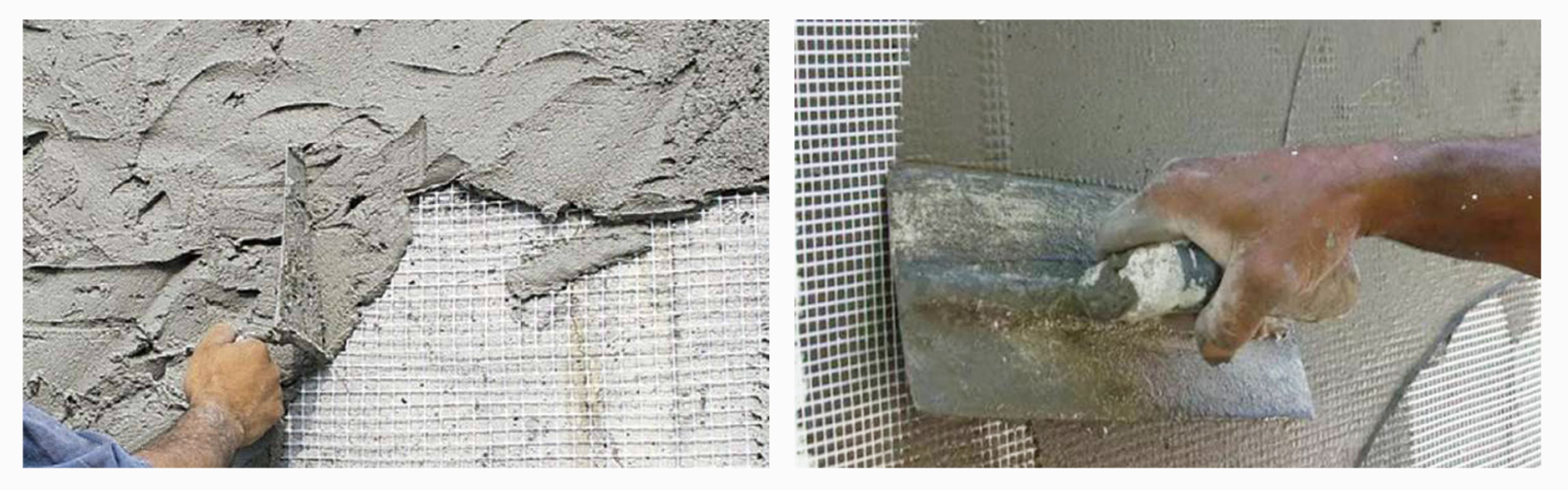

3.Fiberglass Mesh for Plastering

Fiberglass mesh for plastering is specifically designed to be embedded in plaster applications. This type of mesh enhances the strength and flexibility of plaster, reducing the likelihood of cracking and improving adhesion.

Advantages of Using Fiberglass Mesh for Plastering:

Enhanced Flexibility: The mesh allows for slight movements in the substrate without causing cracks in the plaster.

Improved Adhesion: Fiberglass mesh helps plaster adhere better to surfaces, ensuring a smooth and durable finish.

Lightweight and Easy to Work With: Fiberglass mesh for plastering is lightweight, making it easy to cut and apply during the plastering process.

4.Fiberglass Mesh Roll

Fiberglass mesh rolls are available in various sizes and are used for a wide range of applications, including reinforcement, repair, and insulation. The flexibility of fiberglass mesh rolls makes them suitable for both large and small projects.

Uses of Fiberglass Mesh Roll:

Reinforcement: Fiberglass mesh rolls can be used to reinforce concrete slabs, walls, and other structures, providing added strength and durability.

Insulation: When used in conjunction with insulation materials, fiberglass mesh rolls can help improve energy efficiency in buildings.

Surface Preparation: Fiberglass mesh rolls can be applied to surfaces before the application of plaster or stucco, ensuring a strong bond and reducing the risk of cracking.

5. Fiberglass Mesh for Stucco

Fiberglass mesh for stucco is specifically designed to be used in stucco applications, providing reinforcement and improving the overall durability of the stucco finish. This type of mesh is typically embedded in the base coat of stucco to enhance its strength.

Benefits of Using Fiberglass Mesh for Stucco:

Crack Resistance: Fiberglass mesh helps to prevent cracking in stucco finishes, ensuring a long-lasting and aesthetically pleasing appearance.

Weather Resistance: The mesh provides additional protection against the elements, making stucco finishes more resilient to moisture and temperature fluctuations.

Versatile Application: Fiberglass mesh for stucco can be used on various surfaces, including concrete, masonry, and wood, making it a versatile choice for builders and contractors.

Conclusion

Fiberglass mesh is an invaluable material in the construction and renovation industry, offering a range of applications that enhance the strength, durability, and longevity of various structures. From fiberglass mesh for concrete to fiberglass mesh tape, plastering, and stucco, each type serves a specific purpose that contributes to the overall quality of construction projects.

As the construction industry continues to evolve, the demand for innovative materials like fiberglass mesh is likely to grow. Its lightweight nature, corrosion resistance, and cost-effectiveness make it an attractive option for builders and contractors looking to improve the performance of their projects. Whether you are working on a small renovation or a large commercial construction, incorporating fiberglass mesh into your work can lead to better results and increased satisfaction for both builders and clients alike.

Contact Us:

Phone number/WhatsApp:+8615823184699

Email: marketing@frp-cqdj.com

Website: www.frp-cqdj.com

Post time: Nov-18-2024