In recent years, the demand for fiberglass rods has been growing steadily across various industries. From construction and infrastructure to sports and recreation, fiberglass poles are a popular choice due to their versatility, durability, and cost-effectiveness. This article will explore the growing importance of fiberglass rods and its impact on different industries, as well as the potential for further growth in the future.

Fiberglass rods, also known as fiberglass-reinforced plastic (FRP) rods, are composite materials made from a combination of glass fibers and polymer resins. This combination results in a lightweight yet extremely strong material that is resistant to corrosion, heat, and chemicals. These properties make fiberglass rods ideal for a variety of applications, including construction, electrical power, marine, automotive, and sports equipment.

One of the key factors driving the growing demand for fiberglass rods is its superior strength-to-weight ratio. Compared to traditional materials such as steel or aluminum, fiberglass rods are considerably stronger and lighter. This makes them an attractive option for applications where weight reduction is critical, such as the aerospace, automotive, and marine industries. Additionally, the corrosion-resistant properties of fiberglass rods make it an excellent choice for outdoor and marine applications where exposure to moisture and harsh environmental conditions is a concern.

In the construction industry, fiberglass bars have a wide range of applications, including the reinforcement of concrete structures, electrical insulation, and structural support for buildings and bridges. Using fiberglass poles in construction offers several advantages, including high tensile strength, corrosion resistance, and ease of installation. As the construction industry continues to prioritize the sustainability and longevity of structures, the demand for fiberglass rods is expected to grow as a durable and cost-effective alternative to traditional materials.

In addition, fiberglass rods are increasingly used in electric utility applications such as overhead power line insulators, cross arms, and pole structures. The non-conductive properties of fiberglass rods make them ideal for electrical insulation, reducing the risk of electrical accidents and increasing the overall safety of electrical distribution systems. As global power demand continues to grow, the power utility industry's need for reliable and durable infrastructure is expected to drive demand for fiberglass rods.

In the marine industry, fiberglass rods are used to build hulls, masts, and other structural components due to their lightweight and corrosion-resistant properties. The durability of fiberglass poles in marine environments, where exposure to salt water and harsh weather conditions is common, has led to their increasing adoption by boat builders and marine engineers. As the demand for lightweight, energy-efficient, and low-maintenance vessels continues to grow, fiberglass poles are expected to play a key role in meeting these requirements.

Additionally, the sports and entertainment industry has also witnessed a surge in the use of fiberglass rods in the manufacturing of sporting equipment such as fishing rods, golf club shafts, and archery bows. The flexibility, strength, and lightweight properties of fiberglass poles make them ideal for sports equipment manufacturers looking for enhanced performance and durability. As demand for high-performance sports equipment continues to rise, fiberglass poles are expected to remain a popular choice among athletes and outdoor enthusiasts.

From a sustainability perspective, fiberglass bars offer several environmental benefits compared to traditional materials. The production of fiberglass rods uses less energy and produces fewer emissions than the manufacture of steel or aluminum, making it a more environmentally friendly option. In addition, fiberglass rods have a long service life and low maintenance requirements, helping to reduce material waste and reduce their life cycle environmental impact.

Looking ahead, the future of fiberglass bars appears promising, with continued research and development dedicated to enhancing their properties and expanding their applications. Advances in manufacturing processes and materials technology are expected to further improve the performance and cost-effectiveness of fiberglass rods, making them a more attractive option for various industries.

In summary, the growing demand for fiberglass rods across multiple industries is a testament to its versatility, durability, and cost-effectiveness. From construction and electrical installations to marine and sports equipment, fiberglass rods are the material of choice because of their superior performance and environmental benefits. As industries continue to prioritize lightweight, durable, and sustainable solutions, demand for fiberglass rods is expected to grow, driving further innovation and expansion of their applications.

The following summarizes the types of fiberglass rods and the advantages of our production factory:

Types of fiberglass rods:

1. Solid fiberglass rod: Uniform diameter, commonly used in applications such as construction, electrical insulation, and structural support.

2. Hollow fiberglass rods: Fiberglass tubes have a hollow core and are often used in applications where weight reduction is critical, such as aerospace, marine and sports equipment.

3. Pultruded fiberglass rods: Fiberglass bars are manufactured using a pultrusion process that produces high-strength, corrosion-resistant rods suitable for a variety of industrial and recreational applications.

Advantages of our production facility:

1. Advanced Manufacturing Technology: Our production facility is equipped with state-of-the-art machinery and technology, allowing us to produce high-quality fiberglass rods with precise dimensions and consistent performance.

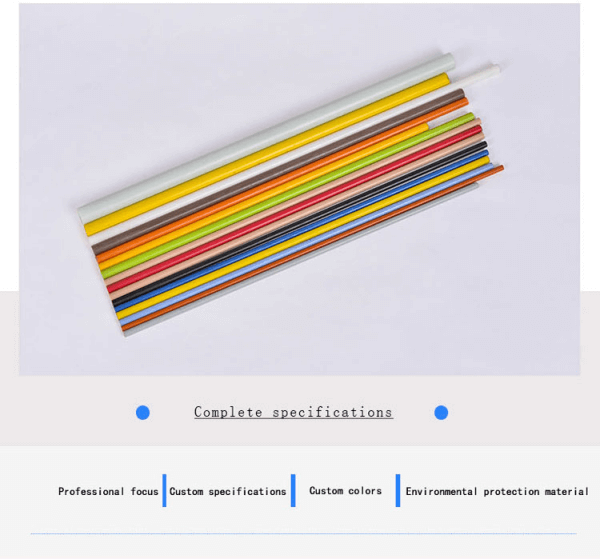

2. Customization capabilities: We offer customization options for fiberglass rods, including different diameters, lengths, and surface finishes to meet customers' specific requirements.

3. Quality Control Standards: Our production facilities adhere to strict quality control standards to ensure that our fiberglass rods meet industry regulations and customer expectations for durability, strength and reliability.

4. Sustainable practices: We prioritize sustainability in our production processes, utilizing environmentally friendly materials and energy-saving manufacturing techniques to minimize our impact on the environment.

5. Research and Development: Our production facility invests in ongoing research and development to innovate and improve the performance of fiberglass rods to stay at the forefront of technological advancements in the industry.

Contact Us:

Phone number/WhatsApp:+8615823184699

Email: marketing@frp-cqdj.com

Website: www.frp-cqdj.com

Post time: Sep-02-2024