Fiberglass Roving: The quality of these products is critical as it directly affects the performance, durability, and overall effectiveness of the final composite material. This news will tell about the importance and advantages of our factory's fiberglass direct roving.

Understanding Direct Roving

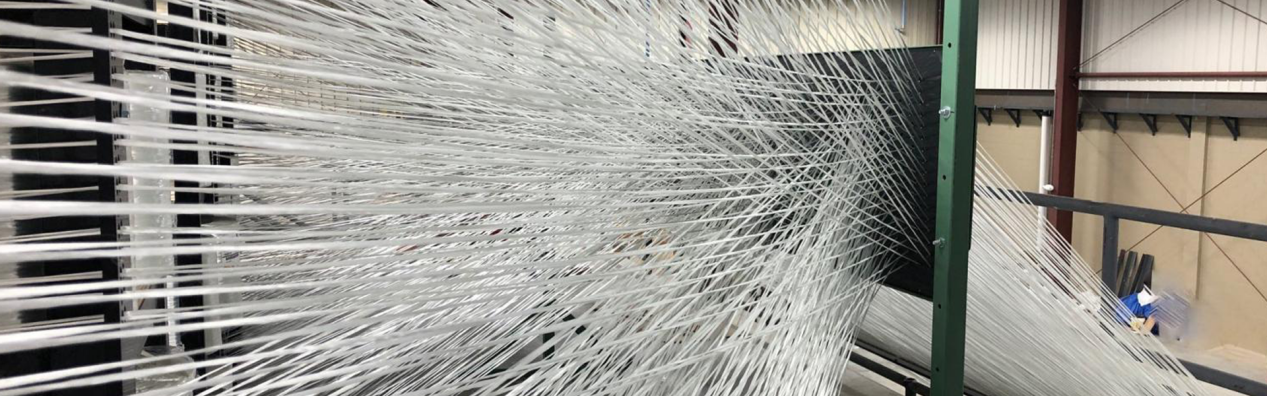

Direct roving is a type of fiberglass reinforcement that consists of continuous strands of glass fibers. These strands are bundled together and can be used in various forms, such as fiberglass woven fabrics, fiberglass mats, or as standalone rovings. The primary purpose of direct roving is to provide strength and rigidity to composite materials, making them suitable for a wide range of applications.

Types of Direct Roving

Thermosetting fiberglass direct roving

Thermosetting fiberglass direct roving is a type of composite material made from continuous strands of glass fibers that are bundled together and coated with a thermosetting resin. This material is designed for use in a variety of applications, particularly in industries such as automotive, aerospace, construction, and marine, where high strength, durability, heat, and chemical resistance are critical.

Key Characteristics:

Composition:

Made from continuous glass fibers, which provide high tensile strength and rigidity.

Coated with a thermosetting resin, which hardens upon curing, creating a strong and stable structure.

Thermosetting Properties:

The resin used in thermosetting fiberglass cures irreversibly when heat is applied, resulting in a hard, inflexible material that can withstand high temperatures and harsh environments.

Once cured, it does not melt or soften, making it suitable for applications requiring thermal stability.

Direct Roving:

The term “direct roving” refers to the continuous strands of glass fibers that are delivered in a single bundle, allowing for easy handling and processing.

This form is ideal for a variety of manufacturing processes, including braiding, braiding, and shaping.

Applications:

Commonly used in the production of composite materials for automotive parts, boat hulls, wind turbine blades, and construction materials.

Suitable for applications requiring lightweight yet strong materials, such as in the aerospace industry.

Advantages:

High strength-to-weight ratio, making it an excellent choice for lightweight structures.

Excellent resistance to moisture, chemicals, and UV radiation.

Good electrical insulation properties.

Processing:

Can be processed using various methods, including hand lay-up, spray-up, and automated processes like filament winding and resin transfer molding (RTM).

Conclusion:

Thermosetting fiberglass direct roving is a versatile and robust material that combines the strength of glass fibers with the durability of thermosetting resins. Its unique properties make it suitable for a variety of demanding applications, aiding the development of lightweight and high-performance composite structures.

Thermoplastic fiberglass direct roving

Thermoplastic fiberglass direct roving is a type of composite material made from continuous strands of glass fibers that are bundled together and designed to be used with thermoplastic resins. Unlike thermosetting resins, thermoplastic resins can be melted and reformed multiple times without undergoing a chemical change, making them highly versatile for various applications.

Key Characteristics:

Composition:

Composed of continuous glass fibers that provide high tensile strength and rigidity.

Designed to be compatible with thermoplastic resins, such as polypropylene, nylon, or polycarbonate.

Thermoplastic Properties:

Thermoplastic resins can be heated to a pliable state and then cooled to form a solid structure, allowing for easy processing and recycling.

This property enables manufacturers to reshape or remold the material without degradation, making it suitable for applications requiring flexibility and reusability.

Direct Roving:

The term “direct roving” refers to the continuous strands of glass fibers delivered in a single bundle, facilitating easy handling and processing.

This form is ideally suited to a variety of manufacturing processes, including injection molding, compression molding, and filament winding.

Applications:

Commonly used in automotive components, consumer goods, electrical housings, and industrial applications where lightweight and durable materials are required.

Suitable for applications that benefit from the ability to be reshaped or recycled.

Advantages:

High strength-to-weight ratio, providing excellent mechanical properties while keeping the overall weight low.

Good impact resistance and flexibility compared to thermosetting composites.

Easier to process and recycle, contributing to more sustainable manufacturing practices.

Processing:

Can be processed using various methods, including injection molding, extrusion, and thermoforming, allowing for efficient production of complex shapes and designs.

Conclusion:

Thermoplastic fiberglass direct roving is a versatile and durable material that combines the strength of glass fibers with the reprocessability of thermoplastic resins. Its unique properties make it suitable for a wide range of applications, particularly in industries where flexibility, recyclability, and high performance are essential.

The Role of Product Quality

The quality of fiberglass rovings, including both fiberglass direct roving, is crucial for several reasons:

1. Mechanical Performance

The mechanical performance of composite materials is heavily influenced by the quality of the fiberglass rovings used. High-quality rovings exhibit superior tensile strength, flexural strength, and impact resistance. This is essential for applications where the composite material will be subjected to stress, such as in automotive parts or structural components in buildings.

2. Consistency and Reliability

Product quality ensures consistency in the manufacturing process. High-quality direct rovings are produced under strict quality control measures, resulting in uniformity in fiber diameter, tensile strength, and other critical properties. This consistency is vital for manufacturers who rely on predictable performance from their materials, as it reduces the risk of defects and failures in the final product.

3. Durability and Longevity

The durability of composite materials is directly linked to the quality of the fiberglass rovings used. High-quality rovings are less prone to degradation over time, ensuring that the final product maintains its strength and performance throughout its intended lifespan. This is particularly important in applications exposed to harsh environmental conditions, such as marine or outdoor structures.

4. Cost-Effectiveness

While high-quality fiberglass rovings may come with a higher initial cost, they often prove to be more cost-effective in the long run. The reduced likelihood of defects, failures, and the need for repairs or replacements can lead to significant savings for manufacturers and end-users alike. Investing in quality materials can enhance the overall value of the final product.

Factors Influencing Product Quality

Several factors contribute to the quality of E-glass direct roving:

1. Raw Materials

The quality of the raw materials used in the production of fiberglass rovings is a critical determinant of the final product’s quality. High-grade glass fibers, additives, and sizing agents contribute to the overall performance characteristics of the fiberglass roving. Manufacturers must source their materials from reputable suppliers to ensure the integrity of their products.

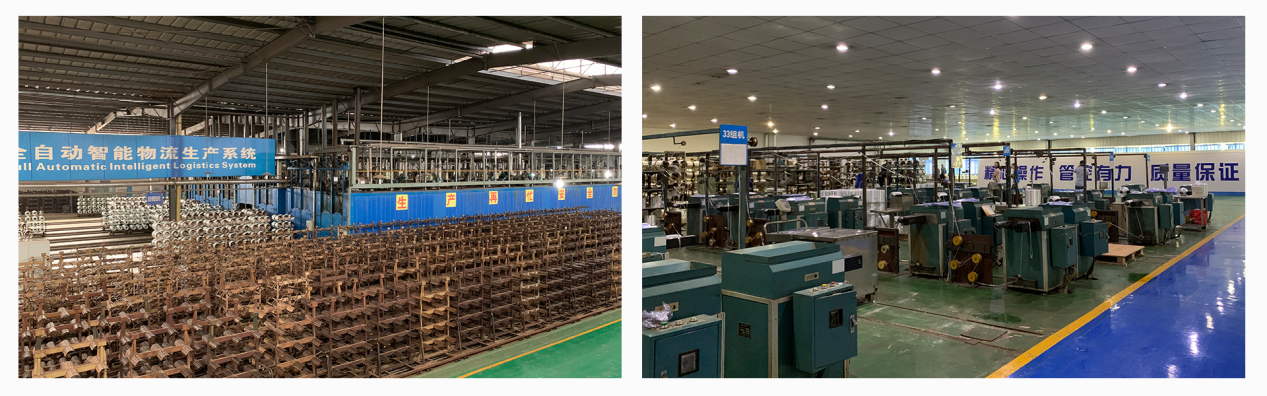

2. Manufacturing Process

The manufacturing process itself plays a significant role in determining product quality. Advanced production techniques, such as controlled drawing and precise sizing application, can enhance the mechanical properties of the fiberglass rovings. Additionally, adherence to industry standards and certifications ensures that the manufacturing process meets the required quality benchmarks.

3. Quality Control Measures

Implementing rigorous quality control measures throughout the production process is essential for maintaining high product quality. This includes regular testing of raw materials, in-process inspections, and final product evaluations. Manufacturers that prioritize quality control are better positioned to deliver reliable and consistent fiberglass rovings.

Applications of High-Quality Fiberglass Rovings

The applications of fiberglass direct roving and E-glass direct roving are vast and varied, with high-quality products being essential in many sectors:

1. Automotive Industry

In the automotive sector, high-quality fiberglass rovings are used to manufacture lightweight yet strong components, such as body panels, bumpers, and structural reinforcements. The use of fiberglass composites helps improve fuel efficiency and reduce emissions by lowering vehicle weight.

2. Aerospace Industry

The aerospace industry demands materials that can withstand extreme conditions while maintaining structural integrity. High-quality E-glass direct rovings are used in aircraft components, providing the necessary strength and lightweight characteristics required for flight.

3. Construction and Infrastructure

In construction, fiberglass rovings are utilized in reinforced concrete, roofing materials, and other structural applications. The durability and corrosion resistance of high-quality fiberglass composites make them ideal for use in harsh environments, extending the lifespan of buildings and infrastructure.

4. Marine Applications

The marine industry relies heavily on fiberglass composites for boat hulls, decks, and other components. High-quality fiberglass rovings ensure that these materials can withstand the rigors of saltwater exposure, UV radiation, and mechanical stress.

Contact Us:

Phone number/WhatsApp:+8615823184699

Email: marketing@frp-cqdj.com

Website: www.frp-cqdj.com

Post time: Nov-05-2024