What is Fiberglass Surface Mat?

Introduction

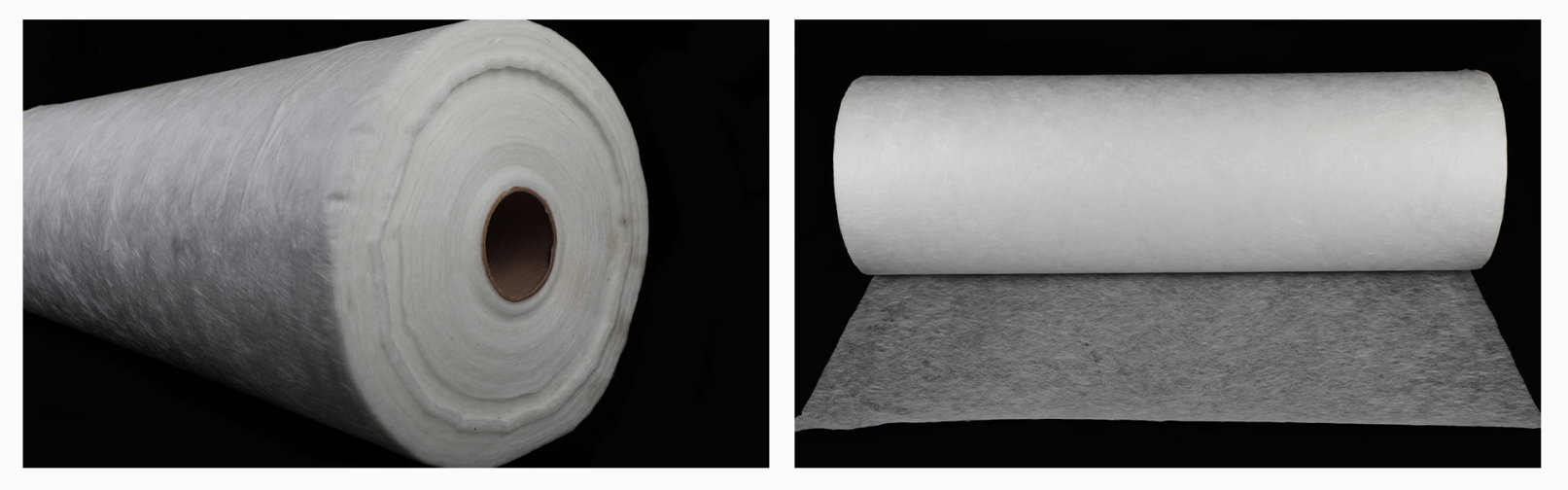

Fiberglass surface mat is a type of composite material made from randomly oriented glass fibers that are bonded together using a resin or adhesive. It is a non-woven mat that typically has a thickness ranging from 0.5 to 2.0 mm and is designed to provide a smooth surface finish and enhance the mechanical properties of composite materials.

Applications of Fiberglass Surface Mat

Fiberglass surface mats are versatile materials used in a variety of industries due to their unique properties, including strength, lightweight nature, and excellent surface finish. Here are some key applications of fiberglass surface mats:

Automotive Industry:

Body Panels: These are used in the manufacturing of lightweight body panels, hoods, and fenders to improve fuel efficiency and performance.

Interior Components: Applied in dashboards, door panels, and other interior parts to enhance aesthetics and reduce weight.

Aerospace:

Aircraft Components: Utilized in the production of fuselage and wing components where a high strength-to-weight ratio is critical.

Interior Linings: Employed in cabin interiors for lightweight and durable finishes.

Construction:

Roofing Systems: Used in roofing materials to provide a smooth surface and enhance durability against weather conditions.

Wall Panels: Applied in wall systems for both structural support and aesthetic finishes.

Marine:

Boat Hulls: Commonly used in the construction of boat hulls and decks to provide a smooth finish and resistance to water and corrosion.

Interior Finishes: Employed in the interiors of boats for a clean and durable surface.

Consumer Goods:

Sporting Equipment: Used in the production of lightweight and durable sporting goods, such as surfboards and bicycles.

Furniture: Applied in the manufacturing of furniture pieces that require a high-quality finish and durability.

Industrial Applications:

Chemical Storage Tanks: Used in the lining of tanks and containers to provide resistance to corrosive chemicals.

Pipes and Ducts: Employed in the production of pipes and ducts for HVAC systems, offering durability and resistance to environmental factors.

Wind Energy:

Wind Turbine Blades: Used in the construction of wind turbine blades, where lightweight and strong materials are essential for efficiency and performance.

Manufacturing Process of Fiberglass Surface Mat

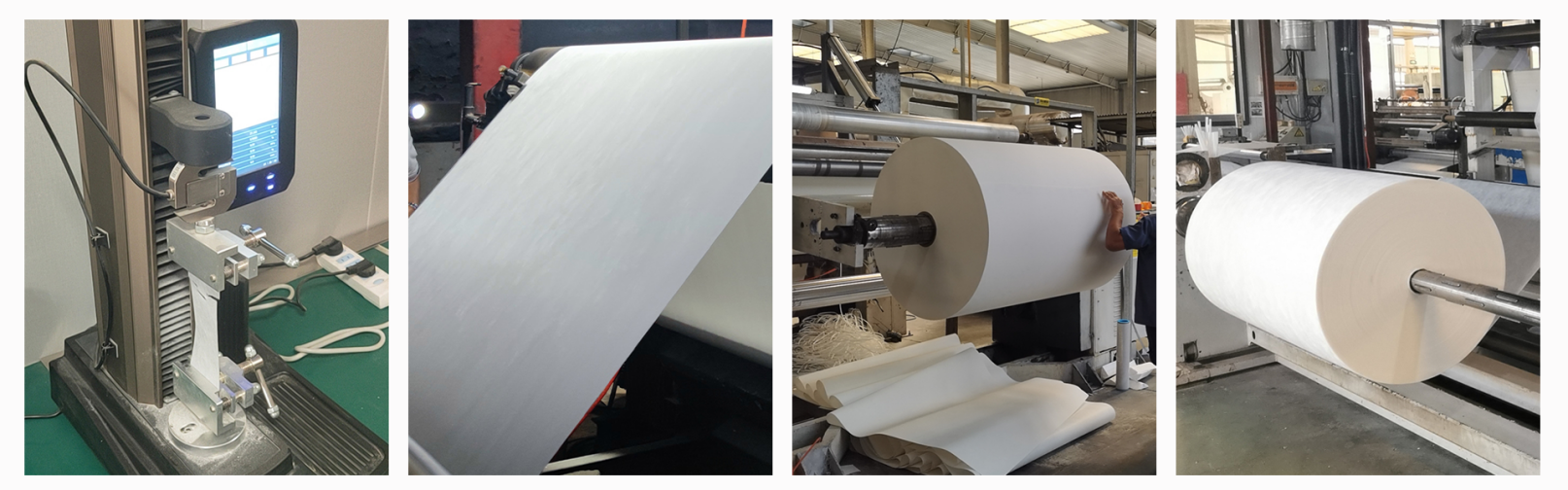

Fiber Production: The process begins with the production of glass fibers. Raw materials, primarily silica sand, are melted in a furnace and then drawn into fine strands through a process called fiberization.

Fiber Orientation: The glass fibers are then randomly oriented and laid out on a conveyor belt or a forming machine. This random arrangement helps distribute strength evenly across the mat.

Binder Application: A binder resin is applied to the laid-out fibers. This can be done through spraying, dipping, or other methods to ensure even coverage.

Curing: The mat is then subjected to heat or pressure to cure the binder, which solidifies and bonds the fibers together. This step is crucial for achieving the desired mechanical properties and durability.

Cutting and Finishing: After curing, the fiberglass surface mat is cut to the required dimensions and may undergo additional finishing processes, such as trimming or surface treatment, to enhance its performance characteristics.

Quality Control: Finally, the mats are subjected to quality control checks to ensure they meet industry standards and specifications before being packaged and shipped for use in various applications.

Advantages of Fiberglass Surface Mats

Fiberglass surface mats are widely used in various industries due to their numerous benefits. Here are some key advantages of using fiberglass surface mats:

High Strength-to-Weight Ratio:

Fiberglass surface mats provide excellent strength while remaining lightweight. This characteristic is particularly beneficial in applications where reducing weight is crucial, such as in automotive and aerospace industries.

Corrosion Resistance:

Fiberglass is inherently resistant to corrosion, making surface mats ideal for use in harsh environments, such as marine applications and chemical storage. This resistance extends the lifespan of products made with fiberglass mats.

Versatile Applications:

Fiberglass surface mats can be used in a wide range of applications, including automotive parts, construction materials, marine components, and consumer goods. Their versatility allows for use in both structural and aesthetic applications.

Smooth Surface Finish:

The use of fiberglass surface mats contributes to a high-quality, smooth surface finish in composite products. This is particularly important in applications where appearance matters, such as in automotive exteriors and decorative laminates.

Ease of Use:

Fiberglass surface mats are relatively easy to handle and can be cut to size, making them convenient for manufacturers. They can be easily integrated into various composite manufacturing processes, such as hand lay-up, spray-up, and vacuum infusion.

Thermal Insulation:

Fiberglass has good thermal insulation properties, which can be advantageous in applications requiring temperature control, such as in building materials and HVAC systems.

Fire Resistance:

Many fiberglass surface mats are inherently fire-resistant, making them suitable for applications where fire safety is a concern, such as in construction and automotive industries.

Cost-Effectiveness:

While the initial cost of fiberglass materials may be higher than some alternatives, their durability and low maintenance requirements can lead to long-term cost savings. The longevity of products made with fiberglass surface mats often outweighs the initial investment.

Customization:

Fiberglass surface mats can be manufactured with various properties, such as different fiber orientations, thicknesses, and resin types, allowing for customization to meet specific performance requirements.

Fiberglass surface mats are resistant to moisture, UV radiation, and other environmental factors, making them suitable for outdoor applications and environments with fluctuating conditions.

How to Choose the Right Fiberglass Surface Mat

Choosing the right fiberglass surface mat involves several considerations to ensure it meets your specific application needs. Here are some key factors to guide your decision:

1. Understand the Purpose

Surface Finish: Determine if the mat is intended for a smooth surface finish or for structural reinforcement.

Application: Identify whether it will be used in boat building, automotive parts, construction, or other applications.

2. Weight and Thickness

Weight: Surface mats come in various weights (measured in grams per square meter). Choose a weight that suits your application; heavier mats provide more strength but may be less flexible.

Thickness: Consider the thickness of the mat, as it can affect the final product’s weight and strength.

3. Resin Compatibility

Ensure the mat is compatible with the type of resin you plan to use (e.g., polyester, vinyl ester, epoxy). Some mats are designed specifically for certain resin systems.

4. Performance Characteristics

Strength: Look for mats that provide the necessary tensile and flexural strength for your application.

Flexibility: If the mat needs to conform to complex shapes, ensure it has the required flexibility.

5. Surface Finish Requirements

If a smooth finish is critical, consider using a mat designed for a high-quality surface finish, such as a fine-woven mat or a mat with a specific surface treatment.

6. Environmental Resistance

If the final product will be exposed to harsh environments (e.g., moisture, chemicals, UV light), choose a mat that offers good resistance to these conditions.

7. Cost Considerations

Compare prices among different types and brands of surface mats, but also consider the long-term value based on performance and durability.

8. Manufacturer Reputation

Research manufacturers for quality and reliability. Look for reviews and testimonials from other users.

9. Consult with Experts

If you are unsure, consult with suppliers or industry experts who can provide recommendations based on your specific needs.

10. Test Samples

If possible, obtain samples to test the mat’s performance in your application before making a bulk purchase.

By considering these factors, you can choose the right fiberglass surface mat that meets your specific requirements and ensures optimal performance in your application.

Contact Us:

Phone number/WhatsApp:+8615823184699

Email: marketing@frp-cqdj.com

Website: www.frp-cqdj.com

Post time: Nov-05-2024