FRP is currently widely used. In fact, FRP is simply the abbreviation of glass fiber and resin composite. It is often said that glass fiber will adopt different forms according to different products, processes and performance requirements of use, so as to achieve different uses. Require. Today we will talk about the different forms of common glass fibers.

1. Twistless Roving

Untwisted roving is further divided into direct untwisted roving and assembled untwisted roving. Direct roving is a continuous fiber drawn directly from glass melt, also known as single-strand untwisted roving. The assembled roving is a roving made of multiple strands of parallel strands, which is simply a synthesis of multiple strands of direct roving.

Teach you a little trick, how to quickly distinguish between direct roving and assembled roving? One strand of roving is drawn out and shakes quickly. The one that remains is direct roving, and the one that is dispersed into multiple strands is assembled roving.

2. Texturized Rovings

Bulked roving is made by impacting and perturbing glass fibers with compressed air, so that the fibers in the roving are separated and the volume is increased, so that it has both the high strength of continuous fibers and the bulkiness of short fibers.

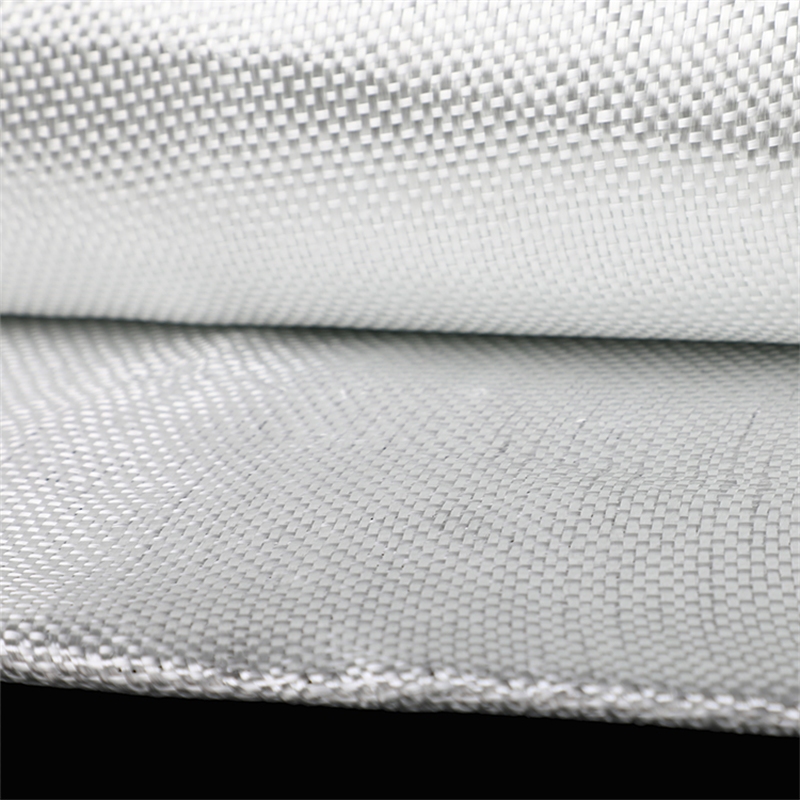

3. Fiberglass woven roving

Fiberglass woven roving is a roving plain weave fabric with warp and weft woven at 90° up and down, also known as woven fabric. The strength of the woven roving is mainly in the warp and weft directions.

4. Axial fabric

Axial fabric is made by weaving glass fiber direct untwisted roving on a multi-axial braiding machine.

The more common angles are 0°, 90°, 45°, -45°, which are divided into unidirectional cloth, biaxial cloth, triaxial cloth and quadriaxial cloth according to the number of layers.

5. G.lass fiber mat

Glass fiber mats are collectively referred to as "mats", which are sheet-like products made of continuous strands or chopped strands that are non-directionally bound together by chemical binders or mechanical action. Mats are further divided into chopped strand mats, stitched mats, composite mats, continuous mats, surface mats, etc. Main applications: pultrusion, winding, molding, RTM, vacuum introduction, GMT, etc.

6. Chopped strands

The fiberglass roving is chopped into strands of a certain length. Main applications: wet chopped (reinforced gypsum, wet thin mat), BMC, etc.

7. Grind the fibers

It is produced by grinding chopped fibers in a hammer mill or ball mill. It can be used as a filler to improve resin surface phenomenon and reduce resin shrinkage.

The above are several common glass fiber forms introduced this time. After reading these forms of glass fiber, I believe that our understanding of it will be further.

Nowadays, glass fiber is the most used reinforcement material at present, and its application is mature and extensive, and there are many forms. On this basis, it is easier to understand the fields of application and combination materials.

Chongqing Dujiang Composites Co., Ltd.

Contact us:

Email:marketing@frp-cqdj.com

WhatsApp:+8615823184699

Tel: +86 023-67853804

Web: www.frp-cqdj.com

Post time: Sep-17-2022