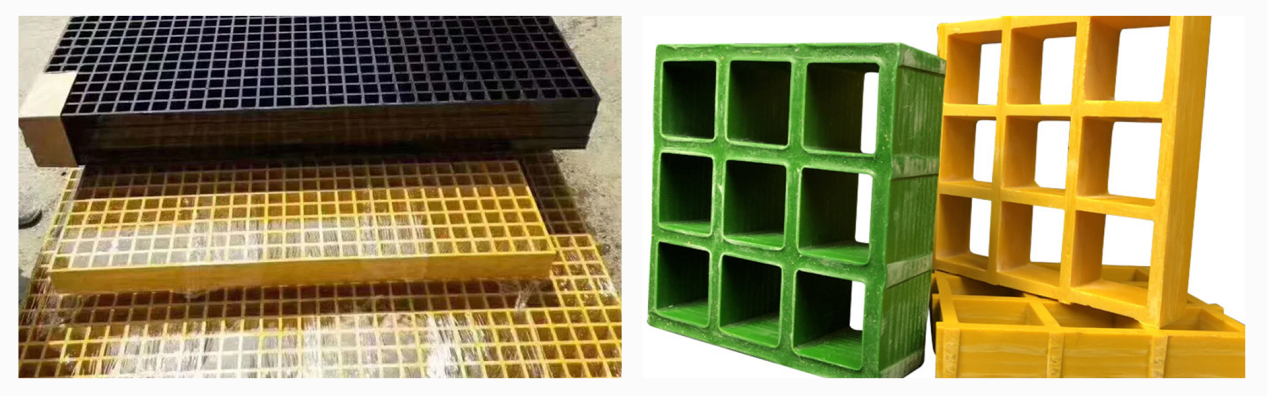

Fiberglass grating is a flat grid material made of glass fiber as the main raw material through weaving, coating and other processes. It has the characteristics of high strength, corrosion resistance, heat insulation, and insulation. It is widely used in many fields such as road construction, bridge reinforcement, chemical corrosion protection, etc. According to different production processes and application fields, fiberglass grating can be divided into the following types:

Classified according to the weaving process:

Plain fiberglass grating: glass fibers are arranged unidirectionally in parallel, staggered weaving, with better flexibility and tensile strength.

Twill fiberglass grating: glass fibers are interlaced and woven at an angle, providing higher shear resistance than plain grille.

Unidirectional fiberglass grating: all glass fibers are arranged in one direction, providing high tensile strength mainly in one direction.

Categorized by coating material:

Coated fiberglass grating: the surface is coated with polyester, epoxy resin and other materials to enhance its corrosion resistance and durability.

Galvanized fiberglass grating: the surface is galvanized to improve its service life in harsh environments.

PVC coated fiberglass grating: the surface is covered with a layer of PVC film to increase wear resistance and aesthetics.

Categorized by use:

Geotechnical fiberglass grids:It is used to reinforce the soil body and improve the stability and bearing capacity of the roadbed.

Construction fiberglass grating: used for building slabs, walls, etc., play the role of reinforcement and heat insulation.

Decorative fiberglass grating: used for indoor and outdoor decoration, with good decorative effect and practicality.

Chemical fiberglass grating: used in chemical industry operation platform, aisle, etc., with corrosion resistance.

Classification by fiber type:

Continuous fiber grating: made with continuous long fibers, good mechanical properties.

Short-cut fiber grating: the use of short-cut fiber production, relatively low cost.

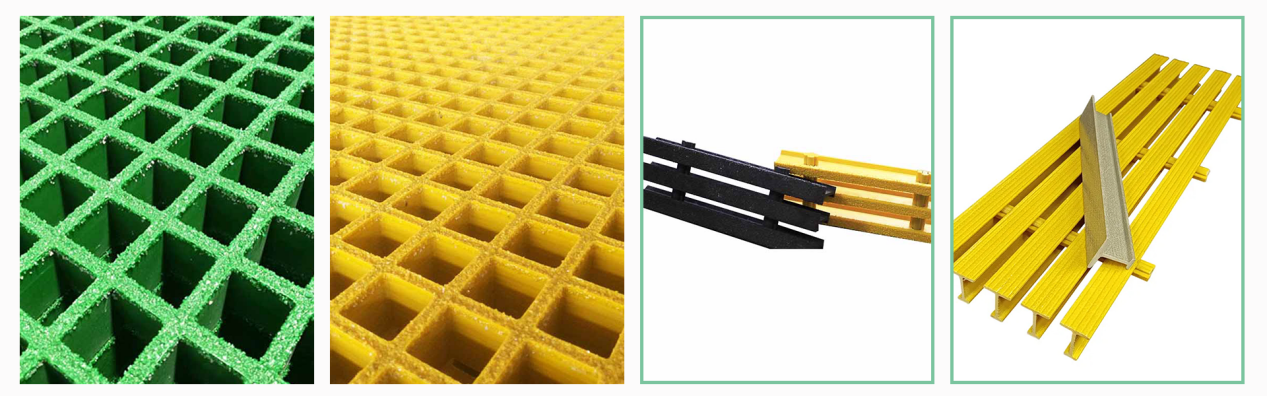

Divided by manufacturing process

Pultruded grating is made by pulling glass fibers through a resin bath and then through a heated die to form a solid shape.

Molded grating is made by placing glass fiber and resin into a mold and then curing it under heat and pressure.

Different types of fiberglass grating in the performance and application differences, choose the right fiberglass grating needs to be based on the needs of the actual project and the use of the environment to determine.

Post time: Dec-21-2024