The sturdiness of fiberglass mats and fiberglass cloth depends on factors such as their thickness, weave, fiber content, and strength after resin curing.

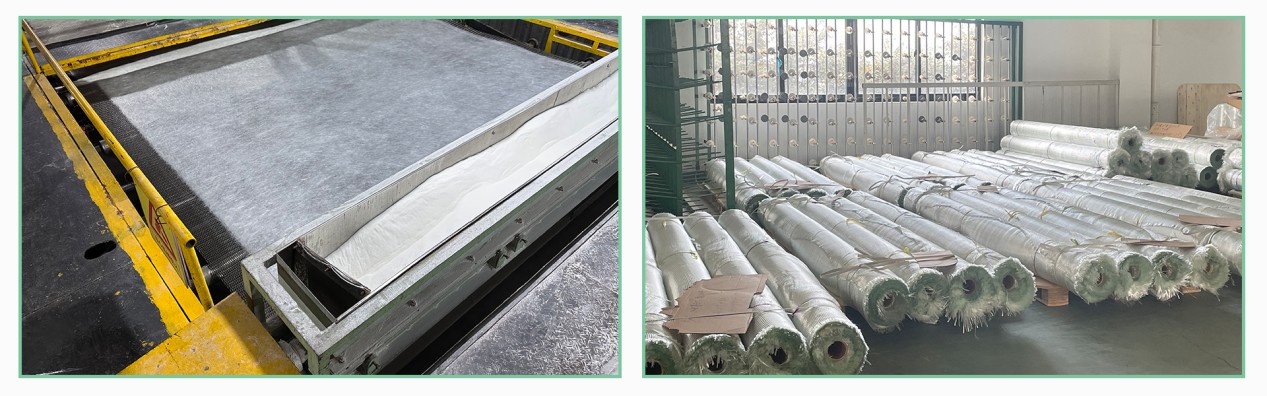

Generally speaking, fiberglass cloth is made of woven glass fiber threads with a certain degree of strength and toughness, and is commonly used in applications that require a certain degree of tensile and flexural strength. The woven structure of glass fiber cloth determines that it has strong tensile properties in certain directions, especially in the direction of fiber arrangement.

Fiberglass mats, on the other hand, are made up of a large number of randomly distributed stacks of chopped strands, which are fixed to each other by means of a binder. This structure allows the mat to have more uniform properties in all directions, but in general, because the fibers are arranged in a random pattern, its tensile strength is usually inferior to that of fiberglass cloth.

Specifically:

- In the case of a single layer of fiberglass cloth, it is usually sturdier than a fiberglass mat of the same thickness, especially when subjected to tensile forces.

- In the case of multi-layer fiberglass cloths that are laminated or specially treated (e.g., impregnated with a resin and cured), the strength is further increased.

- Fiberglass mats are characterized by their softness and isotropy (i.e., the material has the same properties in all directions), but they are usually not as strong as fiberglass cloth when subjected to higher tensile or impact forces.

Therefore, if you want to compare the degree of sturdiness of the two, you need to be specific to the application environment and requirements, as well as their specific specifications and post-treatment processes. In practical applications, the selection of the appropriate material should be based on specific performance requirements and cost considerations.

Post time: Feb-12-2025