CSM (Chopped Strand Mat) and woven roving are both types of reinforcement materials used in the production of fiber-reinforced plastics (FRPs), such as fiberglass composites. They are made from glass fibers, but they differ in their manufacturing process, appearance, and applications. Here's a breakdown of the differences:

CSM (Chopped Strand Mat):

- Manufacturing Process: CSM is produced by chopping glass fibers into short strands, which are then randomly distributed and bonded together with a binder, typically a resin, to form a mat. The binder holds the fibers in place until the composite is cured.

- Fiber Orientation: The fibers in CSM are randomly oriented, which provides isotropic (equal in all directions) strength to the composite.

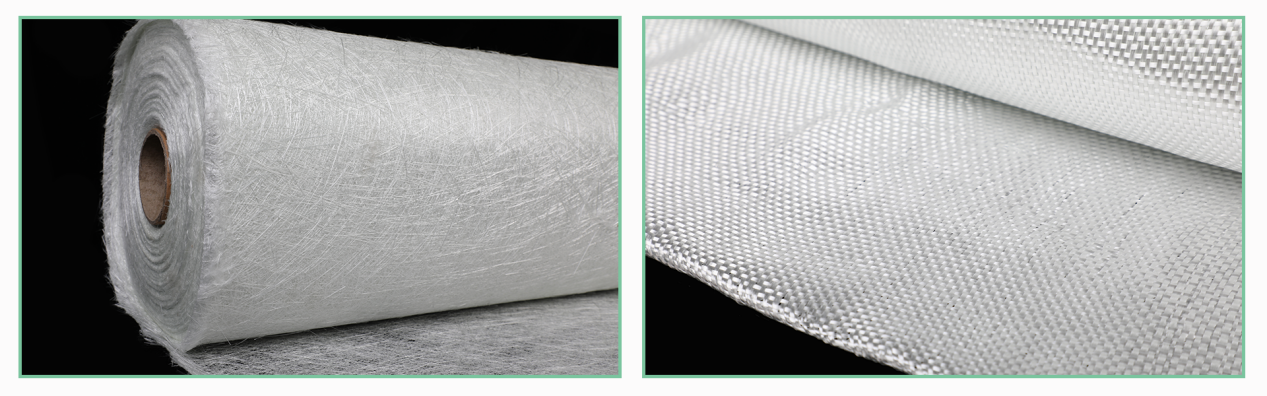

- Appearance: CSM has a mat-like appearance, resembling a thick paper or felt, with a somewhat fluffy and flexible texture.

- Handling: CSM is easier to handle and drape over complex shapes, making it suitable for hand lay-up or spray-up processes.

- Strength: While CSM provides good strength, it is generally not as strong as woven roving because the fibers are chopped and not fully aligned.

- Applications: CSM is commonly used in the production of boats, automotive parts, and other products where a balanced strength-to-weight ratio is needed.

Woven Roving:

- Manufacturing Process: Woven roving is made by weaving continuous glass fiber strands into a fabric. The fibers are aligned in a crisscross pattern, providing a high degree of strength and stiffness in the direction of the fibers.

- Fiber Orientation: The fibers in woven roving are aligned in a specific direction, which results in anisotropic (direction-dependent) strength properties.

- Appearance: Woven roving has a fabric-like appearance, with a distinct weave pattern visible, and it is less flexible than CSM.

- Handling: Woven roving is more rigid and can be more challenging to work with, especially when forming around complex shapes. It requires more skill to lay up properly without causing fiber distortion or breakage.

- Strength: Woven roving offers higher strength and stiffness compared to CSM due to the continuous, aligned fibers.

- Applications: Woven roving is often used in applications requiring high strength and stiffness, such as in the construction of molds, boat hulls, and parts for aerospace and automotive industries.

In summary, the choice between CSM and fiberglass woven roving depends on the specific requirements of the composite part, including the desired strength properties, the complexity of the shape, and the manufacturing process used.

Post time: Feb-12-2025