The downsides of fiberglass rebar

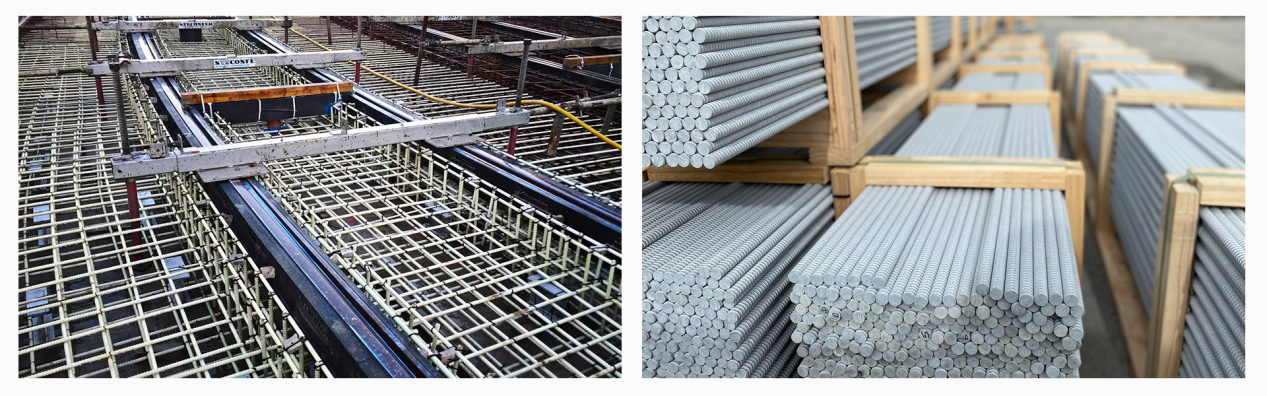

Fiberglass rebar (GFRP, or glass fiber reinforced plastic) is a composite material, consisting of glass fibers and resin, used as an alternative to traditional steel reinforcement in certain structural applications. Despite its many advantages, there are some disadvantages:

1. poorer alkali resistance: glass fibers are susceptible to erosion in alkaline environments, while concrete environments are usually alkaline, which may affect the bonding properties and long-term durability of fiberglass reinforcing bars to concrete.

2. Lower shear strength: Fiberglass reinforcing bars have lower shear strength compared to ordinary steel bars, which limits their use in structural components where higher shear resistance is required.

3. Poor ductility: Fiberglass rebar are not as ductile as conventional steel bars, which means they can withstand less deformation before reaching their ultimate strength, and may not be an ideal choice for some seismic designs.

4. Poor performance at high temperatures: The strength of fiberglass rebar decreases significantly in high temperature environments, which limits their use in applications where they may be exposed to high temperatures.

5. Cost issues: While fiberglass rebar can be cost-saving in some cases, in others they can be more expensive than conventional reinforcing bars due to the unique nature of the material, production and installation.

6. Standardization and design specifications: The application of fiberglass reinforcing bars is relatively new compared to conventional steel reinforcement, and therefore the related standardization and design specifications may not be mature enough, and designers may face limitations in terms of specifications and guidelines for their use.

7. Construction techniques: Installation and construction of fiberglass rebar require special skills and precautions, which may lead to increased construction difficulty and cost.

8. Mechanical anchoring issues: The anchoring of fiberglass rebar can be more complex than that of conventional reinforcing bars, requiring special anchoring designs and construction methods.

Despite these drawbacks, glass fiber rebar remains an attractive option for certain specific applications, especially where non-magnetic, corrosion-resistant or lightweight structural materials are required.

The advantage of fiberglass rebar

GFRP has the following advantages over conventional steel bars (usually carbon steel bars):

1. Corrosion resistance: GFRP bars do not rust, so they last longer in harsh environments such as marine, chemical corrosion or high humidity conditions.

2. Non-magnetic: Frp rebar are non-magnetic, which makes them useful in situations where non-magnetic materials are needed, such as MRI rooms in hospitals or near geological exploration equipment.

3. Lightweight: Fiberglass rebar have a much lower density than conventional steel bars, which makes them easier to handle and install during construction while also reducing the weight of the overall structure.

4. Electrical insulation: Glass fiber reinforced polymer bars are insulators of electricity, so they can be used in structures that require electrical insulation, such as telecommunication towers or support structures for power lines.

5. Design flexibility: GFRP bars can be customized in shape and size as needed, giving designers greater design freedom.

6. Durability: Under the right conditions, fiberglass reinforcing bars can provide long-term durability, reducing maintenance and replacement costs.

7. Fatigue resistance: Fiberglass rebars have good fatigue resistance, which means they maintain their performance under repeated loads, making them suitable for structures subjected to cyclic loads, such as bridges and highways.

8. Low coefficient of thermal expansion: Fiberglass rebars have a low coefficient of thermal expansion, which gives them better dimensional stability in environments with large temperature changes.

9. Reduced concrete cover: Because fiberglass rebars do not rust, the thickness of the concrete cover can be reduced in some designs, reducing the weight and cost of the structure.

10. Improved structural performance: In some applications, fiberglass rebars can work better with concrete and improve the overall performance of the structure, such as in bending and shear resistance.

Despite these advantages, fiberglass rebars also have their limitations, as mentioned earlier. Therefore, when choosing to use glass fiber rebars, it is necessary to comprehensively consider the specific needs of the structure and the environmental conditions.

Post time: Dec-21-2024