Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

• Good wet-out in resins

• Good dispersion

• Good static control

• Suitable for soft mats

Unless otherwise specified, glass fiber products should be stored in a dry, cool, and moisture-proof place.

Glass fiber products should be kept in their original packaging before use. Room temperature and humidity should be kept at -10℃~35℃ and ≤80% respectively.

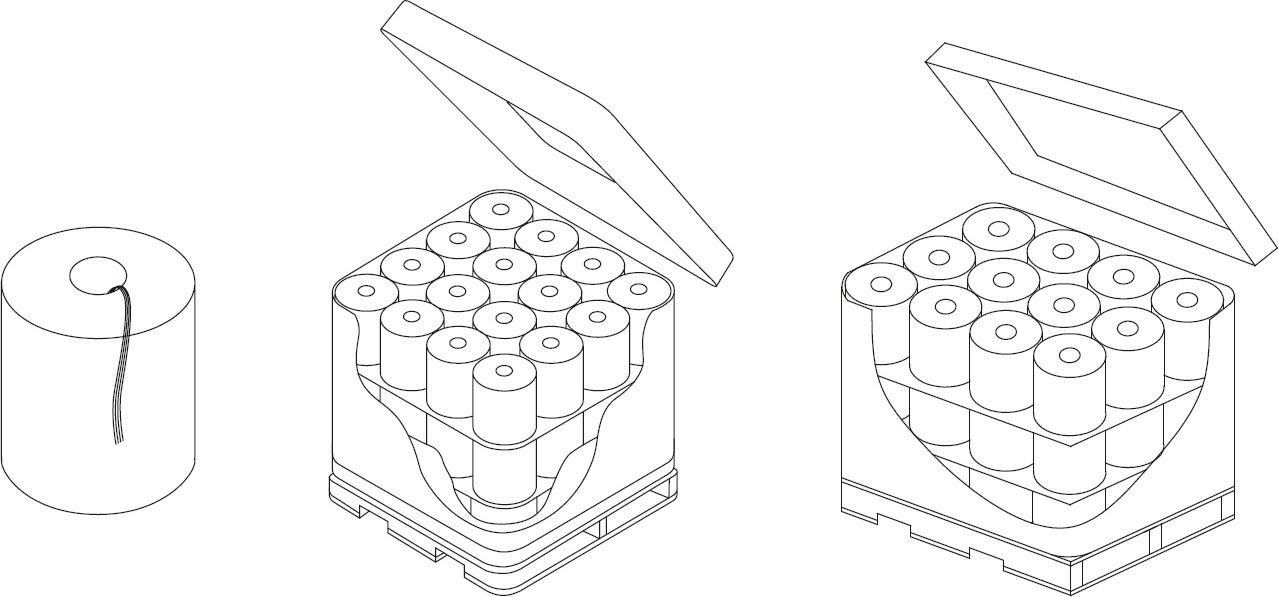

To ensure safety and avoid damaging products, the stacking height of trays should not exceed three layers.

When the trays are stacked in 2 or 3 layers, special attention should be paid to correctly and smoothly move the top tray.

We have many types of fiberglass roving: panel roving, spray up roving, SMC roving, direct roving,c glass roving, and fiberglass roving for chopping.

| Example | E6R12-2400-512 |

| Glass Type | E6 |

| Assembled Roving | R |

| Filament Diameter μm | 12 |

| Linear Density, tex | 2400, 4800 |

| Size Code | 512 |

Unless otherwise specified, the fiberglass products should be stored in a dry, cool, and moisture-proof area.

The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively.

To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high.

When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.

Our fiberglass mats are of several types: fiberglass surface mats, fiberglass chopped strand mats, and continuous fiberglass mats. The chopped strand mat is divided into emulsion and powder glass fiber mats.

| Linear Density (%) | Moisture Content (%) | Size Content (%) | Stiffness (mm) |

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ± 4 | ≤ 0.10 | 0.50 ± 0.15 | 110 ± 20 |

The product can be packed on pallets or in small cardboard boxes.

| Package height mm (in) |

260 (10.2) |

260 (10.2) |

| Package inside diameter mm (in) |

100 (3.9) |

100 (3.9) |

| Package outside diameter mm (in) |

270 (10.6) |

310 (12.2) |

| Package weight kg (lb) |

17 (37.5) |

23 (50.7) |

| Number of layers |

3 |

4 |

3 |

4 |

| Number of doffs per layer |

16 |

12 |

||

| Number of doffs per pallet |

48 |

64 |

36 |

48 |

| Net weight per pallet kg (lb) |

816 (1799) |

1088 (2399) |

828 (1826) |

1104 (2434) |

| Pallet length mm (in) | 1120 (44.1) | 1270 (50) | ||

| Pallet width mm (in) | 1120 (44.1) | 960 (37.8) | ||

| Pallet height mm (in) | 940 (37) | 1200 (47.2) | 940 (37) | 1200 (47.2) |

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.