Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

1.Hand lay-up: Hand lay-up is the main method of FRP production. Fiberglass chopped strand mats, continuous mats and stitched mats can all be used in hand lay-up. The use of stitch-bonded mat can reduce the number of layers and improve the efficiency of hand lay-up operations. However, because the stitchbonded mat contains more chemical fiber stitchbonding threads, the bubbles are not easy to drive away, and the fiberglass products have many needle-shaped bubbles, and the surface feels rough and not smooth. In addition, the stitched mat is a heavy fabric, and the mold coverage is shorter than that of the cut mat and the continuous mat. When making products with complex shapes, it is easy to form voids at the bend. The hand lay-up process requires the mat to have the characteristics of fast resin infiltration rate, easy elimination of air bubbles and good mold coverage.

2.Pultrusion: The pultrusion process is one of the main uses of continuous felt and stitched felt. Generally, it is used in combination with untwisted roving. Using continuous mat and stitched mat as pultruded products can significantly improve the hoop and transverse strength of the products and prevent the products from cracking. The pultrusion process requires the mat to have uniform fiber distribution, high tensile strength, fast resin infiltration rate, good flexibility and mold filling, and the mat should have a certain continuous length.

3.RTM: Resin transfer molding (RTM) is a closed mold molding process. It is composed of two half-moulds, a female mold and a male mold, a pressurizing pump and an injection gun, without a press. The RTM process typically uses continuous and stitch-bonded mats rather than chopped strand mats. The mat sheet is required to have the characteristics that the mat sheet should be easily saturated with resin, good air permeability, good resin scour resistance and good overmoldability.

4.Winding process: chopped strand mats and continuous mats are generally used for winding and forming resin-rich layers mainly used for products, including inner lining layers and outer surface layers. The requirements for the glass fiber mat in the winding process are basically similar to those in the hand lay-up method.

5.Centrifugal casting molding: chopped strand mat is usually used as raw material. The chopped strand mat is pre-laid in the mold, and then the resin is added into the rotating open mold cavity, and the air bubbles are discharged by centrifugation to make the product dense. The mat sheet is required to have the characteristics of easy penetration and good air permeability.

|

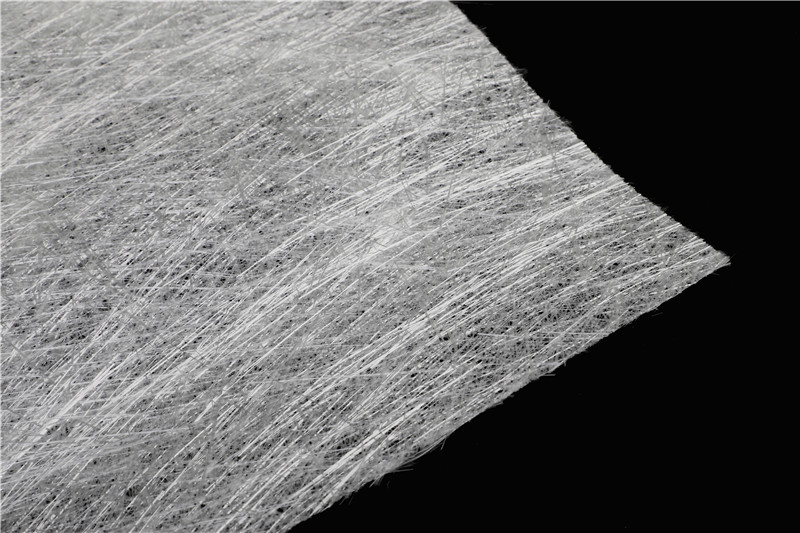

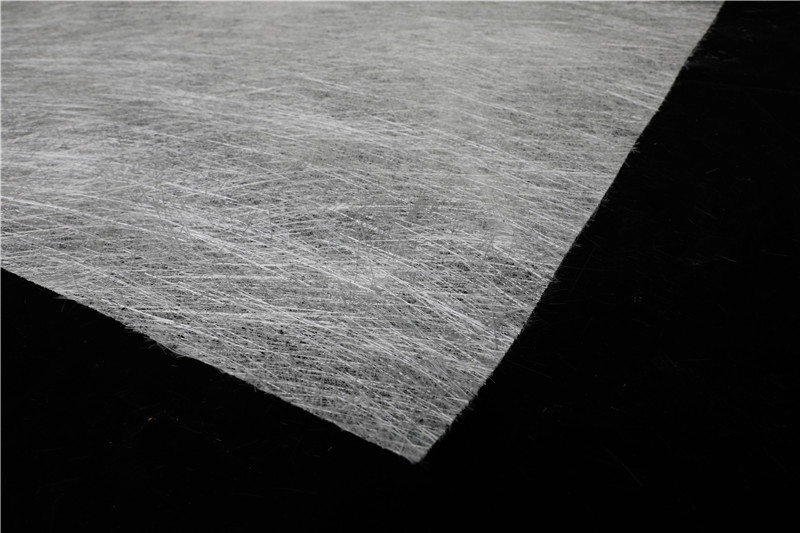

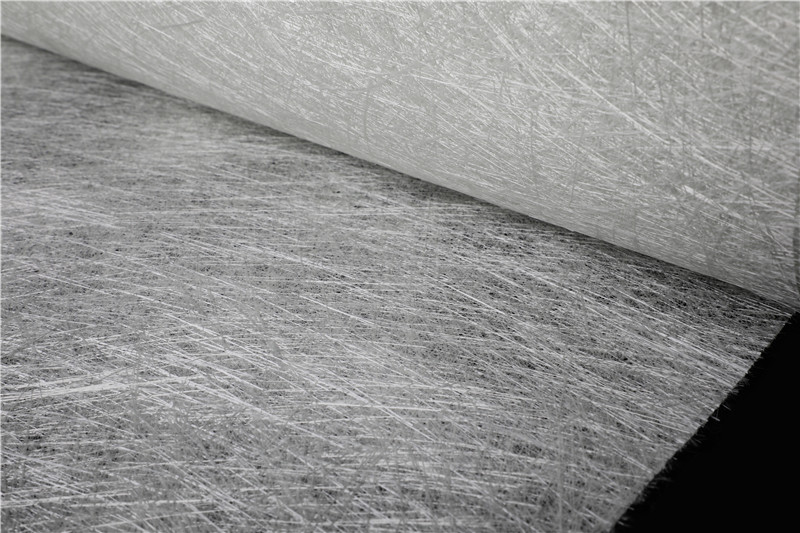

E-Glass Chopped Strand Mat Emulsion |

|||||

|

Quality Index-1040 |

|||||

|

225G |

300G |

450G |

|||

|

Test Item |

Criterion According |

Unit |

Standard |

Standard |

Standard |

|

GLASS TYPE |

G/T 17470-2007 |

% |

R2O<0.8% |

R2O<0.8% |

R2O<0.8% |

|

COUPLING AGENT |

G/T 17470-2007 |

% |

SILANE |

SILANE |

SILANE |

|

Area Weight |

GB/T 9914.3 |

g/m2 |

225±45 |

300±60 |

450±90 |

|

Loi Content |

GB/T 9914.2 |

% |

1.5-12 |

1.5-8.5 |

1.5-8.5 |

|

Tension Strength CD |

GB/T 6006.2 |

N |

≥40 |

≥40 |

≥40 |

|

Tension Strength MD |

GB/T 6006.2 |

N |

≥40 |

≥40 |

≥40 |

|

Water Content |

GB/T 9914.1 |

% |

≤0.5 |

≤0.5 |

≤0.5 |

|

Permeation Rate |

G/T 17470 |

s |

<250 |

<250 |

<250 |

|

Width |

G/T 17470 |

mm |

±5 |

±5 |

±5 |

|

Bending strength |

G/T 17470 |

MPa |

Standard ≧123 |

Standard ≧123 |

Standard ≧123 |

|

Wet ≧103 |

Wet ≧103 |

Wet ≧103 |

|||

|

Test Condition |

|||||

|

Ambent Temperature(℃) |

10 |

Ambient Humidity(%) |

|||

INSTRUCTION

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.