Advantages of Panel Glass Roving

- High Strength and Durability: Panels reinforced with glass roving are robust and can withstand significant stress and impact.

- Lightweight: These panels are much lighter compared to traditional materials like metal, making them ideal for applications where weight savings are crucial.

- Corrosion Resistance: Glass roving panels do not corrode, making them suitable for use in harsh environments, such as marine and industrial applications.

- Versatility: They can be molded into various shapes and sizes, offering flexibility in design and application.

- Thermal Insulation: Composite panels can provide good thermal insulation properties, making them suitable for building applications.

Common Uses

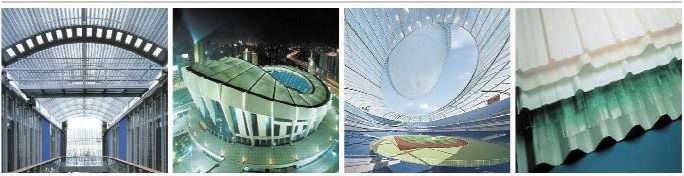

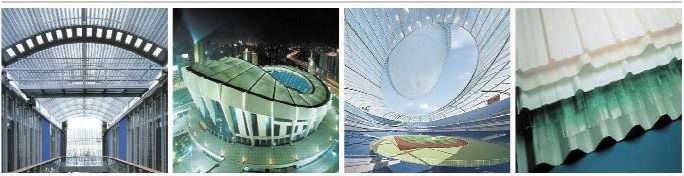

- Construction: Used in building facades, cladding, and structural components.

- Transportation: Employed in vehicle bodies, panels, and parts for cars, boats, and aircraft.

- Industrial: Utilized in equipment housings, piping, and tanks.

- Consumer Goods: Found in sports equipment, furniture, and other durable consumer products.

Product Specification

We have many types of fiberglass roving: fiberglass panel roving, spray-up roving, SMC roving, direct roving, c-glass roving, and fiberglass roving for chopping.

| Model |

E3-2400-528s |

| Type of Size |

Silane |

| Size Code |

E3-2400-528s |

| Linear Density (tex) |

2400TEX |

| Filament Diameter (μm) |

13 |

| Linear Density (%) |

Moisture Content |

Size Content (%) |

Breakage Strength |

| ISO 1889 |

ISO3344 |

ISO1887 |

ISO3375 |

| ± 5 |

≤ 0.15 |

0.55 ± 0. 15 |

120 ± 20 |

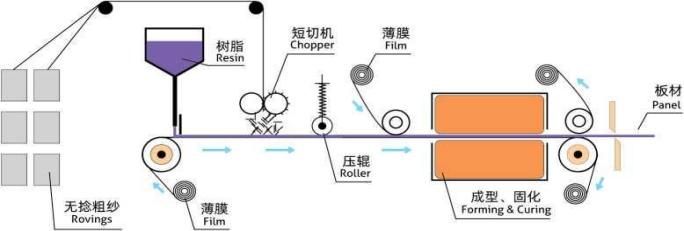

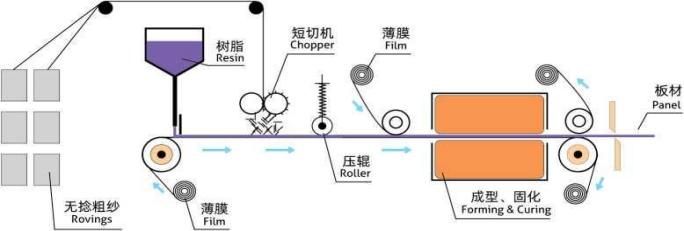

Manufacturing Process of Panel Glass Roving

- Fiber Production:

- Glass fibers are produced by melting raw materials like silica sand and drawing the molten glass through fine holes to create filaments.

- Roving Formation:

- These filaments are gathered together to form roving, which is then wound onto spools for use in further manufacturing processes.

- Panel Production:

- The glass roving is laid into molds or onto flat surfaces, impregnated with a resin (often polyester or epoxy), and then cured to harden the material. The resulting composite panel can be customized in terms of thickness, shape, and surface finish.

- Finishing:

- After curing, the panels can be trimmed, machined, and finished to meet specific requirements, such as adding surface coatings or integrating additional components.