Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Always customer-oriented, and it’s our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for Professional Design Jushi Brand Panel Roving 3200tex, We’re one from the largest 100% manufacturers in China. Several large trading corporations import goods from us, so we will supply you with the most effective price tag with all the same quality if you are interested in us.

Always customer-oriented, and it’s our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for fiberglass assembled roving, fiberglass roving, We firmly think that we now have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

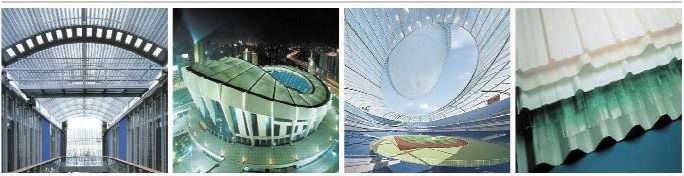

fiberglass panel roving is mainly used to make transparent sheets and transparent felt sheets. The board has the characteristics of lightweight material, high strength, good impact resistance, no white silk, and high light transmittance.

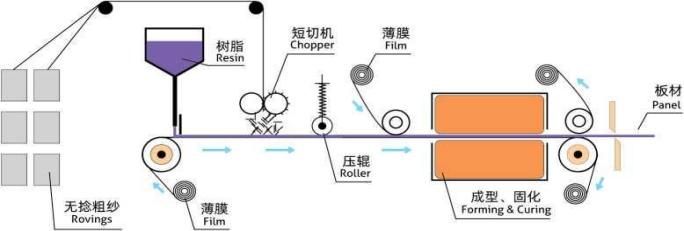

Continuous Panel Molding Process

resin mix is uniformly deposited in a controlled amount onto a moving film at a constant speed. The thickness of the resin is controlled by the draw knife. Fiberglass roving is chopped and uniformly distributed onto the resin. Then a top film is applied forming a sandwich structure. The wet assembly travels through a curing oven to form the composite panel.

We have many types of fiberglass roving: panel roving, spray up roving, SMC roving, direct roving,c glass roving, and fiberglass roving for chopping.

| Model | E3-2400-528s |

| Type of Size | Silane |

| Size Code | E3-2400-528s |

| Linear Density (tex) | 2400TEX |

| Filament Diameter (μm) | 13 |

| Linear Density (%) | Moisture Content | Size Content (%) | Breakage Strength |

| ISO 1889 | ISO3344 | ISO1887 | ISO3375 |

| ± 5 | ≤ 0.15 | 0.55 ± 0. 15 | 120 ± 20 |

(Building and Construction / Automotive /Agriculture/Fibreglass Reinforced Polyester)

• Unless otherwise specified, the fiberglass products should be stored in a dry, cool, and moisture-proof area.

• The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at – 10℃~35℃ and ≤80% respectively.

• To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high.

• When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallets

Always customer-oriented, and it’s our ultimate goal to get not only by far the most reputable, trustable, and honest supplier, but also the partner for our customers for Professional Design Jushi Brand Panel Roving 3200tex, for FRP Transparent, Translucent and Opaque Sheet, We’re one from the largest 100% manufacturers in China. Several large trading corporations import goods from us, so we will supply you with the most effective price tag with all the same quality if you are interested in us.

Professional produce China fiberglass roving and fiberglass mat, We firmly think that we now have the full capability to present you with contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise the Same excellent, better selling price; exact selling price, and better quality.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.