Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

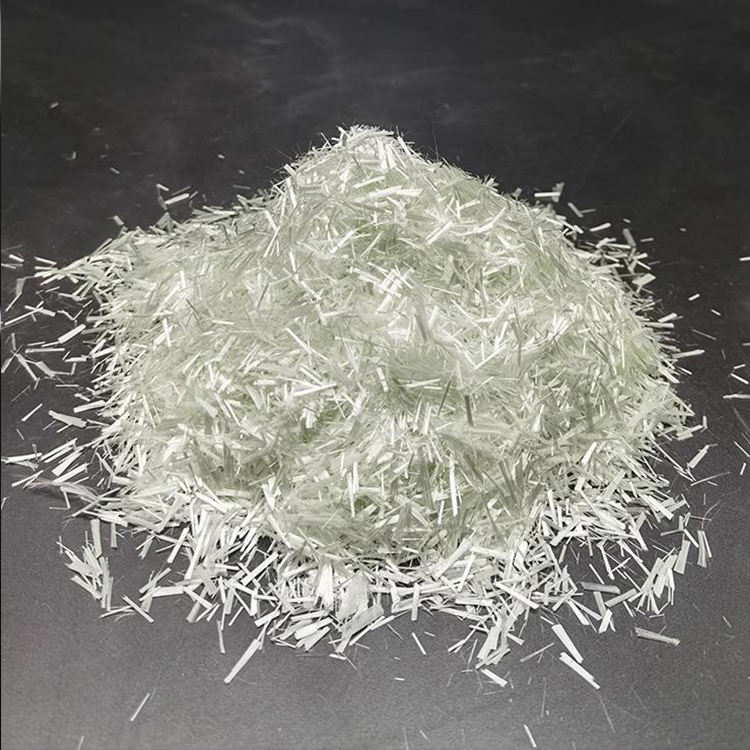

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for Professional Factory Chopped Strand Mat Glass Fibers EMC300, Hope we can easily generate a more glorious long term with you by way of our efforts within the long term.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for China Glass Fiber Chopped Strand Mat and E-Glass Chopped Strand Mat, We have been in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

•To prevent crack of GRC components

•Good Integrity and no static electricity

•Low Fuzz

•Excellent integrated with cement

•Good filament flexible and magnificent strands distribution cement

•Endued good physical and chemical properties for GRC

•Disperse Fast

•Low Dosages

•Harmless

Applying for Fiberglass Reinforced Cement/Concrete

Usage Instruction:

(1)Pre-mixed Fiberglass Chopped Strand

Properties:

It has excellent properties with alkali resistance, stiffness, bundle–state, ageing–proof, Mixed 20 minutes in cement at 50rpm, it can still keep good bundle state, it won’t dispersed to filament.

Purpose:

It is a high integrity Glass Fiber Chopped Strands designed for use in the reinforcement of concrete, renders and mortars. It may be added to conventional

mixes either on site or by prepending with other dry mix components. The low – tex strands permits efficient reinforcement at low dosages. They are particularly suited to the modification of standard concrete mixes for floor screeds and slabs,and for the preparation of prebagged mixes of special mortars and renders.

(2) Water-dispersed Fiberglass Chopped Strands

Properties:

E-glass Glassfiber Applied with water–dispersed size, the strands will disperse well to filaments in water in 10 seconds, and also disperse fast, usage amount less, enlarge strength.

Purpose:

It is typically used at a low level of addition to prevent cracking and improve the performance of ready mix concrete, floor screeds, renders or the special mortar mixes.it can be used for surface crack–proof of GRC

products.

TO USE:

–Mix your resin and hardener, or catalyst

–Next add your Fiberglass Chopped Strands

–It is best to use a paint mixer on your power drill to ensure that all of the strands are properly saturated Thick layers and large pour areas can create excessive heat, so proceed with caution.

Fiberglass Chopped Strand should placed under dryness condition and shall no be open the covering membrane until applying

Dry powder materials can build up static charges, Proper precautions must be taken in the presence of flammable liquids

Fiberglass Chopped Strand can cause eye irritation, harmful if inhaled, may cause skin irritation, harmful if swallowed.Avoid contact with eyes, and contact with skin, Wear goggles and face shield when handing. Always wear an approved respirator. Use only with adequate ventilation. Keep away from heat. Spark and flame. Store handle and use in a manner that minimizes dust generation

In case of contact with skin, wash with warm water and soap. For eyes immediately flush with water for 15 minutes. If irritation continues seek medical attention. If inhaled, move to a fresh air environment. If you have breathing difficulties seek immediate medical attention

Container may be hazardous when empty. Empty containers container product residue.

Key Technical Data:

| CS | Glass Type | Chopped Length(mm) | Diameter(um) | MOL(%) |

| CS3 | E-glass | 3 | 7-13 | 10-20±0.2 |

| CS4.5 | E-glass | 4.5 | 7-13 | 10-20±0.2 |

| CS6 | E-glass | 6 | 7-13 | 10-20±0.2 |

| CS9 | E-glass | 9 | 7-13 | 10-20±0.2 |

| CS12 | E-glass | 12 | 7-13 | 10-20±0.2 |

| CS25 | E-glass | 25 | 7-13 | 10-20±0.2 |

We rely upon strategic thinking, constant modernization in all segments, technological advances, and of course upon our employees that directly participate in our success for Professional Factory for Chopped Strand Mat Glass Fibers EMC300, Hope we can easily generate a more glorious long term with you by way of our efforts within the long term.

We rely upon strategic thinking, constant modernization in all segments, technological advances, and of course upon our employees that directly participate in our success for Professional Factory for Chopped Strand Mat Glass Fibers EMC300, Hope we can easily generate a more glorious long term with you by way of our efforts within the long term.

Professional Factory for China Glass Fiber Chopped Strand Mat and E-Glass Chopped Strand Mat, We have been in continuous service to our growing local and international clients. We aim to be the worldwide leader in this industry and with this in mind; it is our great pleasure to serve and bring the highest satisfaction rates to the growing market.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.