Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Feature

SMC roving is engineered to offer a high level of tensile strength, which is the ability of the material to resist pulling forces without breaking. Additionally, it exhibits good flexural strength, which is the ability to resist bending or deformation under applied loads. These strength properties make SMC roving suitable for producing structural components that require high strength and stiffness.

Application of SMC roving:

1.Automotive Parts: SMC roving is extensively used in the automotive industry for manufacturing lightweight and durable components such as bumpers, body panels, hoods, doors, fenders, and interior trim parts.

2.Electrical and Electronic Enclosures: SMC roving is used to produce electrical and electronic enclosures, such as meter boxes, junction boxes, and control cabinets.

3.Construction and Infrastructure: SMC roving is utilized in the construction industry for manufacturing various building components, including facades, cladding panels, structural supports, and utility enclosures.

4.Aerospace Components: In the aerospace sector, SMC roving is employed for fabricating lightweight and high-strength components such as interior panels, fairings, and structural parts for aircraft and spacecraft.

5.Recreational Vehicles: SMC roving is used in the production of recreational vehicles (RVs), boats, and other marine applications for manufacturing exterior body panels, interior components, and structural reinforcements.

6.Agricultural Equipment: SMC roving is utilized in the agricultural industry for manufacturing components such as tractor hoods, fenders, and equipment enclosures.

| Fiberglass assembled roving | ||

| Glass type | E | |

| Sizing type | Silane | |

| Typical filament diameter (um) | 14 | |

| Typical linear density (tex) | 2400 | 4800 |

| Example | ER14-4800-442 | |

| Item | Linear density variation | Moisture content | Sizing content | Stiffness |

| Unit | % | % | % | mm |

| Test method | ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| Standard Range | ± 5 | ≤ 0.10 | 1.05 ± 0.15 | 150 ± 20 |

| Item | unit | Standard | |

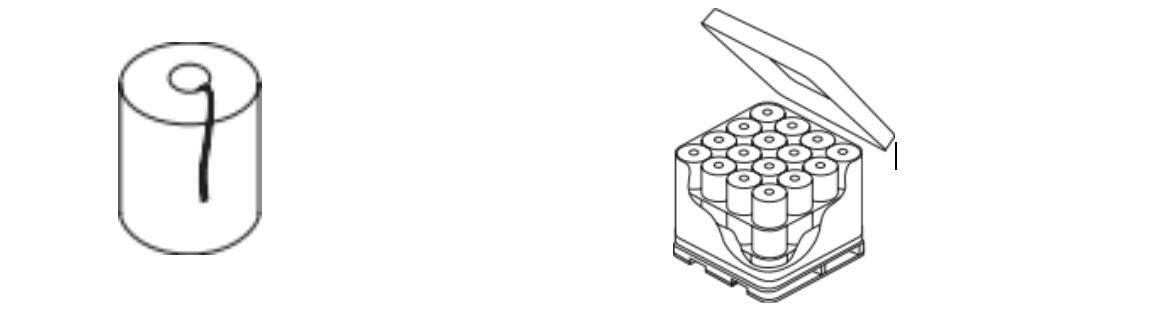

| Typical packaging method | / | Packed on pallets. | |

| Typical package height | mm (in) | 260 (10.2) | |

| Package inner diameter | mm (in) | 100 (3.9) | |

| Typical package outer diameter | mm (in) | 280 (11.0) | |

| Typical package weight | kg (lb) | 17.5 (38.6) | |

| Number of layers | (layer) | 3 | 4 |

| Number of packages per layer | 个 (pcs) | 16 | |

| Number of packages per pallet | 个 (pcs) | 48 | 64 |

| Net weight per pallet | kg (lb) | 840 (1851.9) | 1120 (2469.2) |

| Pallet length | mm (in) | 1140 (44.9) | |

| Pallet width | mm (in) | 1140 (44.9) | |

| Pallet height | mm (in) | 940 (37.0) | 1200 (47.2) |

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.