Fiberglass has many applications in the transportation field, including but not limited to the following aspects:

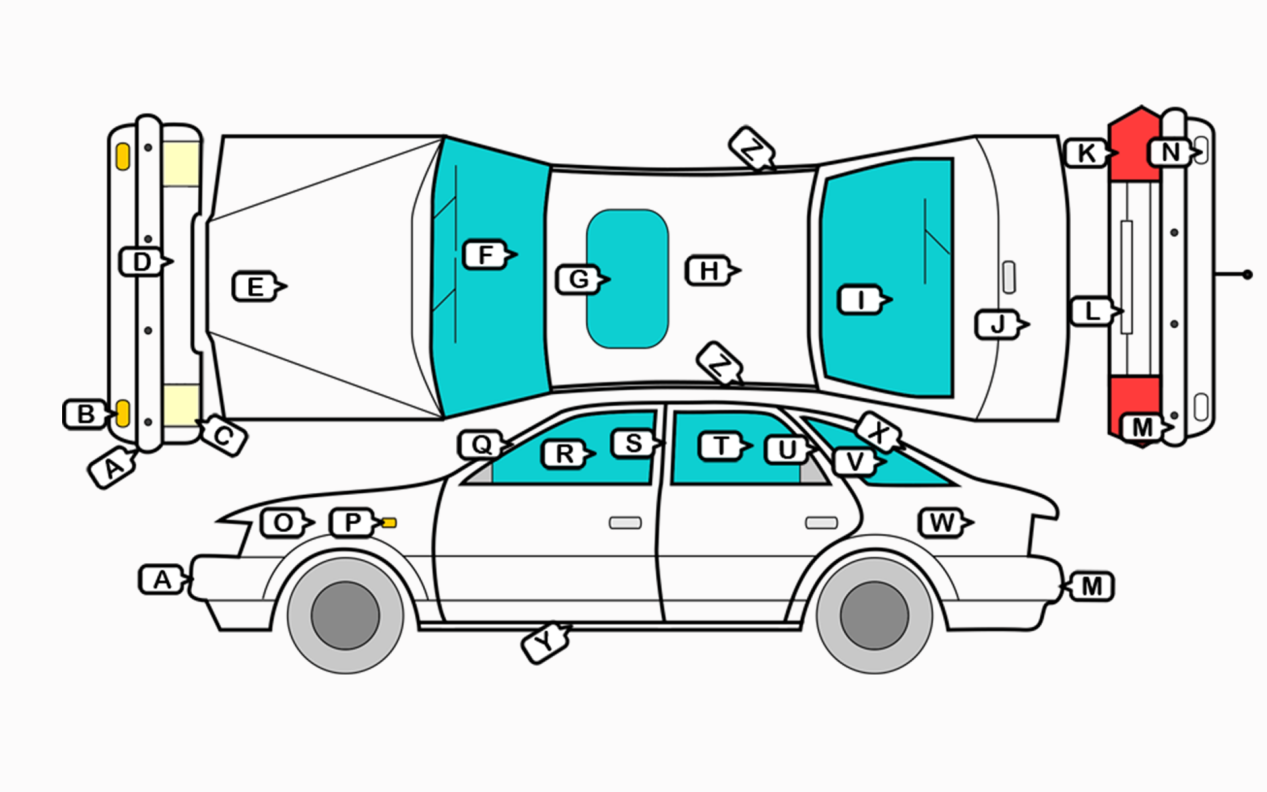

1. Car body manufacturing: Glass fiber can be used to manufacture body parts such as body panels, doors, hoods, etc. of vehicles such as cars, trains, and airplanes. Glass fiber has excellent strength and stiffness, and is lightweight, which can improve the overall performance and fuel efficiency of vehicles.

2. Windows and windshields: Glass fiber can be used to manufacture vehicle windows and windshields, with good transparency and impact resistance, providing good vision and protecting passenger safety.

3. Interior decoration: Glass fiber can also be used to manufacture interior decoration parts such as seats, dashboards, interior panels, etc., with good surface texture and wear resistance.

4. Pavement material: Glass fiber can be mixed with asphalt to make glass fiber-reinforced asphalt concrete, which is used for road paving to improve the durability and load-bearing capacity of the road surface.

In general, the application of glass fiber in the transportation field can improve the performance, safety, and comfort of vehicles, and also help to improve the durability and sustainability of transportation facilities.

Glass fiber roving, glass fiber mat and glass fiber woven roving are widely used in the field of transportation, and can be used to make the following products:

1. Glass fiber roving: Glass fiber roving is a linear material made from glass fiber monofilaments, which can be used to make composite materials. In the field of transportation, glass fiber roving is often used to make glass fiber reinforced plastic (FRP) parts, such as body panels, doors, hoods, etc.

2. Glass fiber mat: Glass fiber mat is a sheet material made of chopped glass fiber by adhesive bonding, which has good flexibility and water absorption. In the field of transportation, glass fiber mat is often used to make sound insulation and heat insulation materials, such as vehicle sound insulation and heat insulation pads, car interiors, etc.

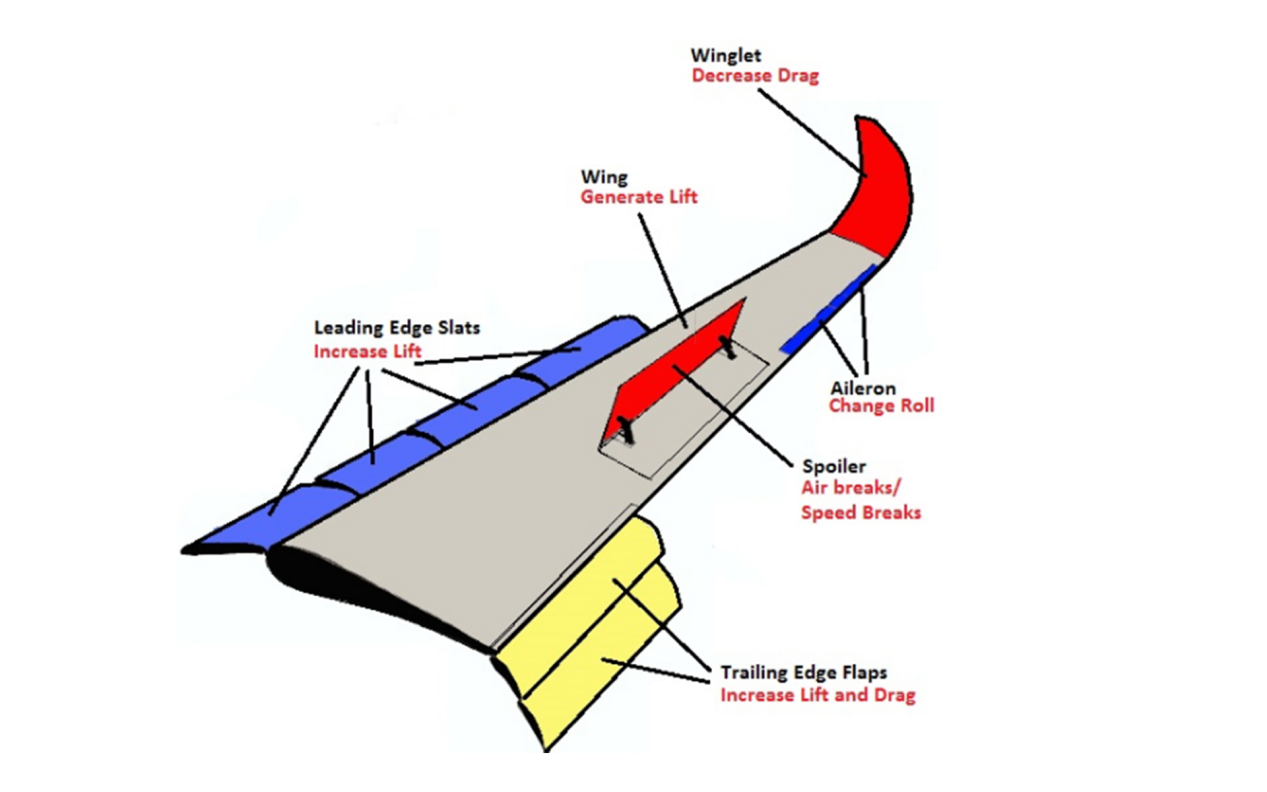

3.Glass fiber cloth: Glass fiber woven roving is a cloth-like material made of glass fiber roving through weaving or non-woven technology, which has good strength and wear resistance. In the field of transportation, glass fiber cloth is often used to make the reinforcing layer of composite materials, such as hulls, aircraft wings, car bodies, etc.

In general, glass fiber roving, glass fiber mat and glass fiber woven roving are widely used in the transportation field. They can be used to make vehicle structural parts, sound insulation and heat insulation materials, reinforcement layers of composite materials and other products.

Our fiberglass roving has the following advantages in the production of body panels, doors and hoods:

1. Lightweight and high strength: Fiberglass roving has a low specific gravity, which can significantly reduce the weight of parts. At the same time, it has excellent strength and stiffness, which can improve the structural strength and impact resistance of parts.

2. Good formability: Fiberglass roving can be formed by injection molding, extrusion, compression molding and other processes, and can produce complex shapes of body panels, doors and hoods to meet the designer's diverse requirements for appearance.

3. Corrosion resistance: Fiberglass roving has good corrosion resistance and can resist corrosion from corrosive media such as chemicals, moisture and salt spray, extending the service life of parts.

4. Excellent surface quality: The surface of parts made of fiberglass roving is smooth and has good texture. It is easy to carry out surface treatment and painting, which improves the appearance quality and assembly accuracy of parts.

5. Cost-effectiveness: Compared with traditional metal materials, fiberglass roving has a lower cost, which can reduce the manufacturing cost of parts and improve the competitiveness of the whole vehicle.

In summary, glass fiber roving has the advantages of light weight, high strength, good formability, corrosion resistance, excellent surface quality and cost-effectiveness in the production of body panels, doors and hoods, so it has broad application prospects in the field of automobile manufacturing.

Chongqing Dujiang has strong strength in the production technology and equipment of glass fiber roving, covering key production processes such as spinning, stretching, and coating.

Spinning technology: Chongqing Dujiang has independently developed advanced spinning technology, which can produce glass fiber roving of various specifications and performances. They continuously optimize the spinning process, improve the uniformity and strength of the roving bundles, and develop new spinning technologies, such as the production technology of high-performance glass fiber roving.

Stretching technology: Chongqing Dujiang has advanced stretching equipment and technology, which can accurately stretch glass fiber roving to improve their strength and modulus. We have also developed new stretching technologies, such as stretching technology for high-strength glass fiber roving, to meet the needs of different application scenarios.

Coating technology: Chongqing Dujiang has perfect coating technology, which can perform various coating treatments on glass fiber roving to improve their performance, such as improving their corrosion resistance, high temperature resistance, antistatic properties, etc. They have also developed new coating technologies, such as environmentally friendly coating technologies, to meet environmental protection requirements.

Independent R&D capability: Chongqing Dujiang has a strong R&D team and has established a complete R&D system, which can continuously improve and innovate the production process and product performance of glass fiber roving. We actively carry out technological innovation and develop a variety of new glass fiber roving products, such as high-strength glass fiber roving, high-modulus glass fiber roving, high-temperature resistant glass fiber roving, etc., to meet the needs of different application scenarios.

In short, Chongqing Dujiang has strong strength in the production technology and equipment of glass fiber roving, and has independent R&D capabilities, which can continuously improve and innovate the production process and product performance of glass fiber roving, providing a solid foundation for its leading position in the global market.

Our glass fiber roving is diverse, with up to eight major categories of glass fiber roving: such as thermosetting direct roving, thermoplastic direct roving, plied roving, thermoplastic chopped roving, water drawing, primary twisted roving, twisted roving and bulked roving.